A trouser belt is a fairly important accessory, which sometimes determines how the whole look will look. And for the belt itself, the most important part is its buckle. A well-chosen buckle not only provides comfort and reliability, but also complements the outfit of both women and men. In the modern world, the choice of buckles is amazing. You can purchase this accessory in any store or order online. But if your ideas about the ideal plaque are so individual that it is impossible to find the right part, then why not try to make it yourself?

A trouser belt is a fairly important accessory, which sometimes determines how the whole look will look. And for the belt itself, the most important part is its buckle. A well-chosen buckle not only provides comfort and reliability, but also complements the outfit of both women and men. In the modern world, the choice of buckles is amazing. You can purchase this accessory in any store or order online. But if your ideas about the ideal plaque are so individual that it is impossible to find the right part, then why not try to make it yourself?

Materials and tools

In order to make a belt buckle with your own hands, you need to stock up on at least a basic set for working with metal. For example, with the following tools:

In order to make a belt buckle with your own hands, you need to stock up on at least a basic set for working with metal. For example, with the following tools:

- device for bending wire;

- vice;

- caliper or other measuring tool;

- brush for processing cuts, sandpaper or file;

- wire cutters;

- soldering iron or rubber hammer for straightening.

It is necessary to select materials based on what kind of final result you want to get. When creating a buckle, you may need the following items.

- Metal parts and plates, such as brass.

- Rivets.

- Solder for joining elements.

- Thick brass, bronze, titanium or copper wire.

- Ammonia or other agent suitable for treating the finished product.

How to make a buckle

The World Wide Web contains a considerable number of all kinds of step-by-step videos and text master classes on making a belt plaque. The most popular options are discussed in detail below.

From metal parts

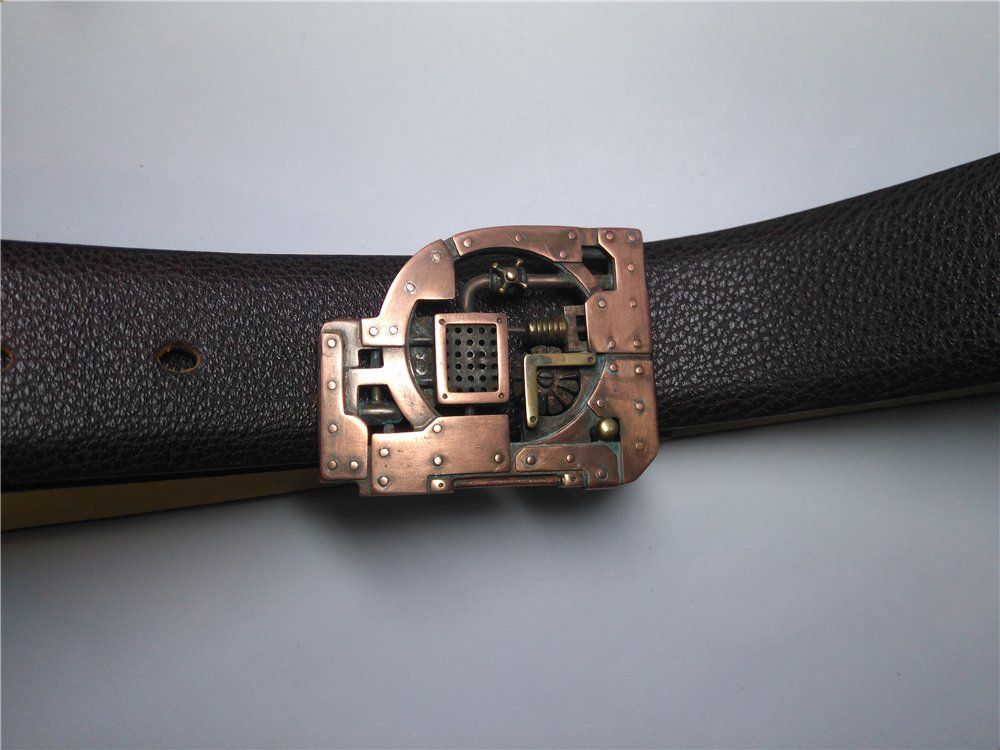

To make a plaque for a belt using this technology prepare as many different metal parts as possible left over from all sorts of old mechanisms. The more choice, the more opportunities for creative exploration and flight of fancy.

To begin with, you can sketch out an initial sketch in real scale and refer to it as you work.

Completing of the work

- It is better to take a fairly large piece of round, oval, square or rectangular shape as a basis. It will serve as the central and main part of the composition. Other, smaller parts will be soldered to it.

- We gradually solder part by part in the order originally intended. You can also improvise on the fly, selecting, cutting and sanding elements so that they look most organic. You can use silver or other metals for solder.

- As the main forms, you can focus on the following: metal plates, meshes, “fans”, gears or hexagons, square or triangular parts, valves and nuts.

- Next you need select and solder the central frame and bracket to the main part using axles and metal plates.

- Now you can do the external “cladding” from thin sheets of the desired material.

- Finally, treat in an ammonia solution.

Wire adjustment buckle

Best for work use wire about 4 mm thick, bending it around a rod with a diameter of 6-7 mm.

- We form the buckle of the desired shape, for example, trapezoidal or rectangular. To make the buckle symmetrical, you can use a caliper to mark each of the four bends. Each bend must be made at an angle of 90°.

IMPORTANT! When forming an angle, pay attention to the distortions that invariably form due to the varying degrees of “springiness” of the metals.

- They somehow deviate from a given angle by a certain number of degrees. It is better to bend the wire a little more than necessary. Then after the impact it will return to the position you need.

- When the three corners of the frame are ready, you can begin making the pin, which will serve as a holding element for the belt. It is necessary to make a full circle with a wire of slightly smaller diameter around the rod matched to it, forming the upper part of the hook.

- Next, you need to cut the free tip to the desired length and sand it.

- Now you can start closing the buckle, having first put the resulting peg on it.

- After closing, all that remains is to align the edges of the buckle with a rubber mallet, which does not require much effort. The belt plaque is ready!

Made from epoxy resin

It would not be superfluous to mention another technology for manufacturing a unique accessory. It is necessary in advance prepare a flat buckle with edges along the outer edge.

Using epoxy resin, which, when hardened, retains its properties and remains transparent, you can fill and insert any image, herbarium, and even small metal elements into the plaque.

4

4