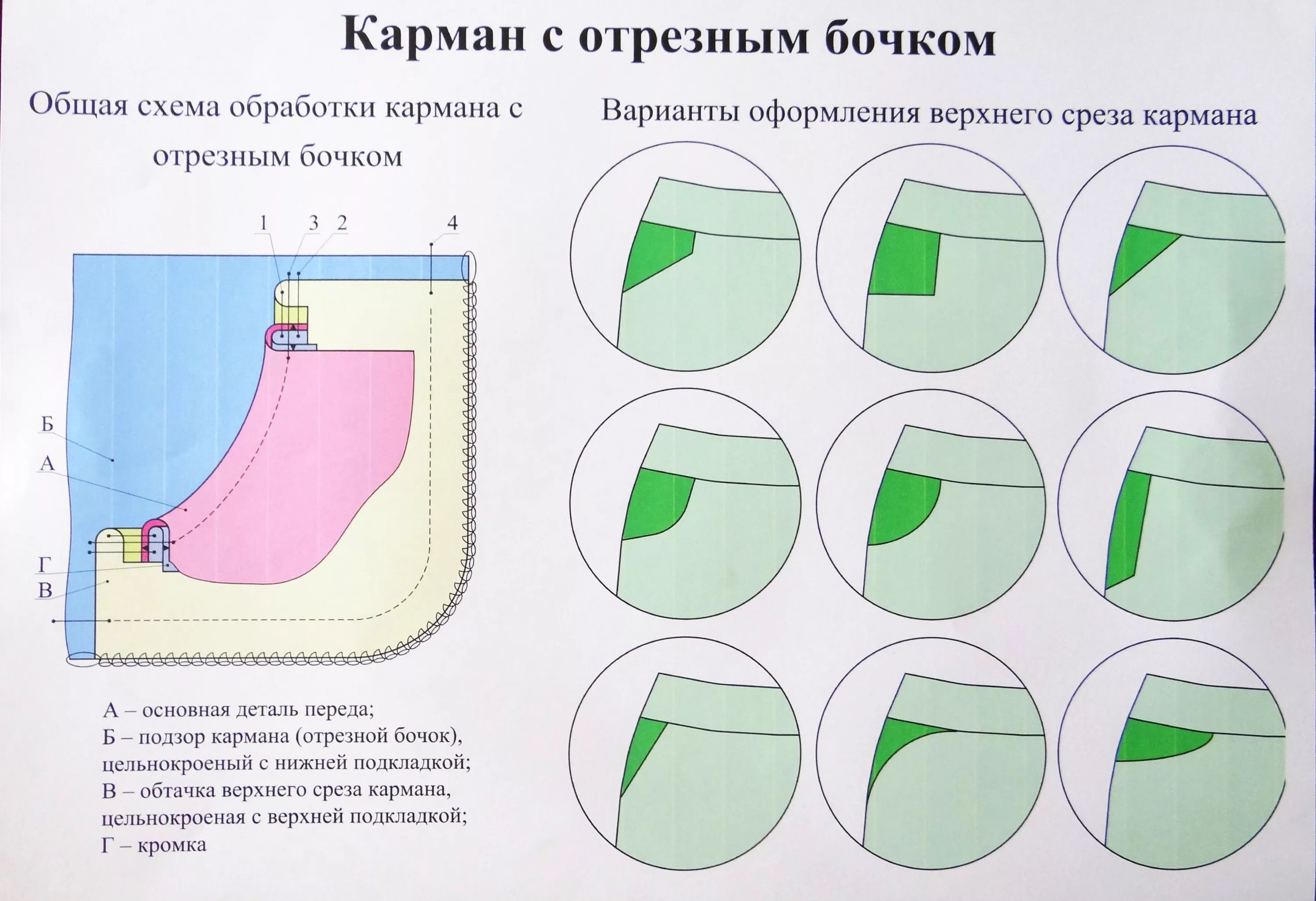

Among the numerous styles, the side pocket with a detachable side occupies a special place. He can be seen in skirts, trousers, and sometimes in dresses. The entry line of such a part is determined by the model. It can be straight, rounded or curly.

Among the numerous styles, the side pocket with a detachable side occupies a special place. He can be seen in skirts, trousers, and sometimes in dresses. The entry line of such a part is determined by the model. It can be straight, rounded or curly.

Making pockets with a cutting side

First, let's start making this additional detail, and then we'll figure out step by step how to sew it on correctly.

What parts does the pocket consist of?

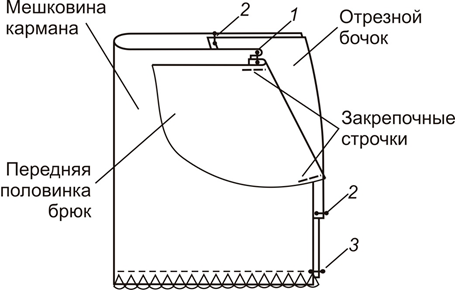

Pocket with cutting flange may consist of 2 or 3 parts. These include burlap and barrel.

The barrel is often a continuation of the main part and forms its inner side.

In trousers, this part can be composite, then the flank is sewn onto burlap.

How to make a pattern

Pocket pattern build on the drawing of the front panel skirts or trousers.

How to mark a place

- For this mark the width and length points of the pocket entrance. On the upper cut of the panel from the top of the side seam, mark the width.

Reference! For the option with a direct entrance, the value is 3–4 cm, for a rounded shape 6–8 cm.The length of the entrance depends on the size of the product, and you need to focus on the size of your palm.

- The length point is marked at a distance of 15–16 cm from the top point of the side seam. A line is drawn along the points found. For classic trousers it is straight, for skirts it is often rounded.

Important! The length of the entrance should be greater than the width of the palm so that the hand fits freely into the pocket.

- To construct the burlap, the length is laid down from the point of the width of the entrance. The width is set off from the side seam. A burlap line is drawn along the marked points. It can be straight or round. The length of the burlap is also determined by the length of the palm.

Uncover

Using the pocket pattern, the parts are cut.

Reference! In garments made from light fabrics, burlap is cut from the main material, in products from dense fabrics from lining fabric.

How to process a pocket with a cutting barrel

Upper edge of entrance

Processing begins with strengthening the upper edge.

- A strip of adhesive interlining is ironed flush to the upper edge of the panel.

- Next, the burlap is placed face down on the front side of the fabric, flush with the top and side edges. It is cleaved with pins and the edge is ground at a distance of 1 cm.

- At the beginning and end of the line, tacks are made.

- Then the burlap is unrolled and waste is performed on the front side at a distance of 0.2 mm.

- Next, iron the entrance to the pocket. To do this, the upper edge of the fabric is bent to the side of the lining to form an edging.

Attention! If the entry line is rounded, notches are required.

The edges

- Then, along the entry line, the edge is stitched with bartacks at the ends of the stitching.

- To fasten the edges of the parts, the fabric of the product is applied according to the marks on the side part, and pre-fastened with pins.

- The edges of the pocket burlap are also pinned together.

- Then the burlap is stitched at a distance of 1 cm, with fastenings at the ends of the lines.

- The edge of the burlap is finished with a zigzag stitch or edging.

- The final step is the operation of fastening the canvas to the barrel along the top and side edges.

- The parts are connected along the top and side edges for further assembly of the product.

0

0