Initially, pockets decorated only men's clothing, but they did not carry a functional load. We figured out using them to store small items a little later. The pocket came into women's fashion quietly and unnoticed; there were even hidden pockets on wedding dresses. But pockets (in particular, patch pockets) became a popular decorative element thanks to Coco Chanel.

Features of patch pockets

This type is often used in sports style clothing, as well as “military” and “safari”.

Reference! A patch pocket is a type that does not involve cuts on the main fabric. It is adjusted over the front side of the product.

Issued:

- Valves.

- With facings.

- Lining.

- Fittings.

- Additional voluminous inserts - a briefcase pocket.

Methods for connecting pocket parts to the main product

Methods:

- We stitch the part along the very edge, the line runs 1-3 mm from the edge.

- We lay the line at a short distance from the edge - 0.5-1.5 cm.

- We connect the pocket parts with a hidden inner stitch.

Advice! Depending on the stretchability of the material, we process the entrance to the pocket with a facing (for easily stretchable elastic fabrics) or simply turn up the seam allowance of the main workpiece (dense, inelastic fabrics).

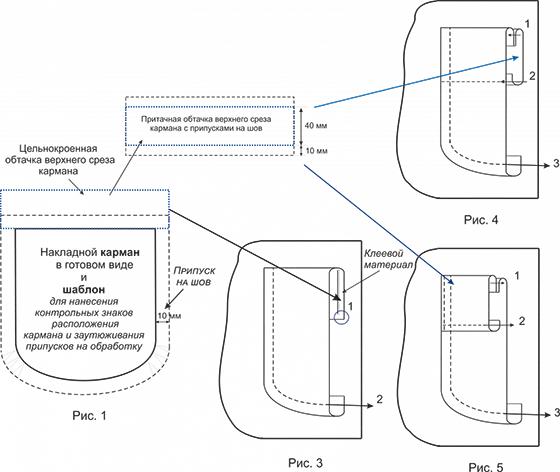

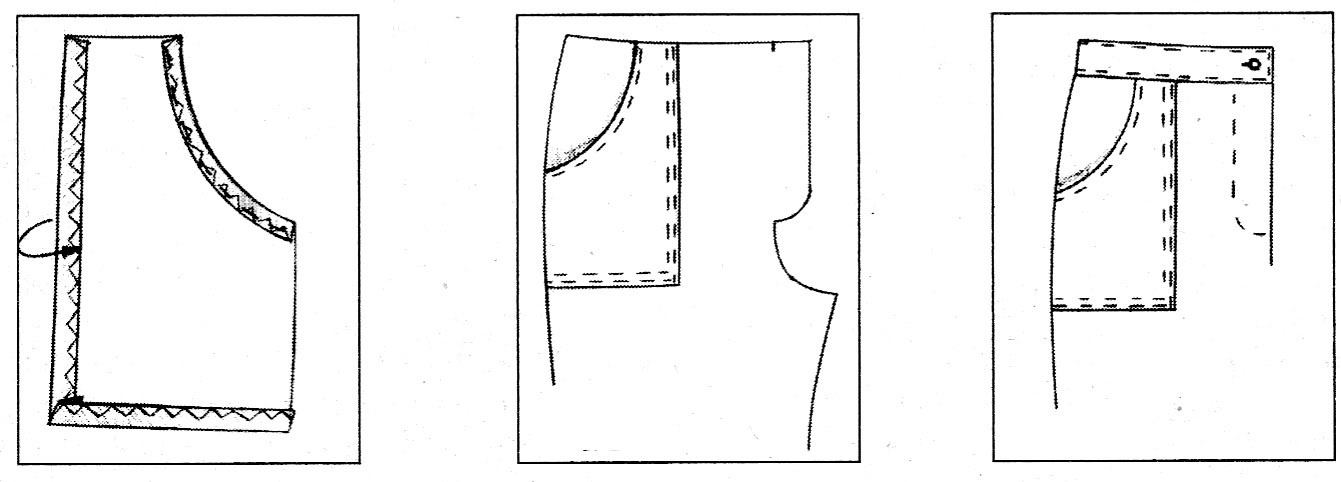

How to cut out a patch pocket correctly?

We decide on the dimensions of the product.

We draw a rectangle (another shape) on paper, the dimensions of which correspond to the necessary ones.

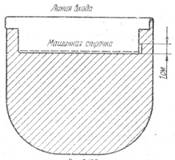

- Sew with machine stitch.

- Iron it.

- Turn it inside out so that on the wrong side there is a lining and a one-piece facing.

- Iron again.

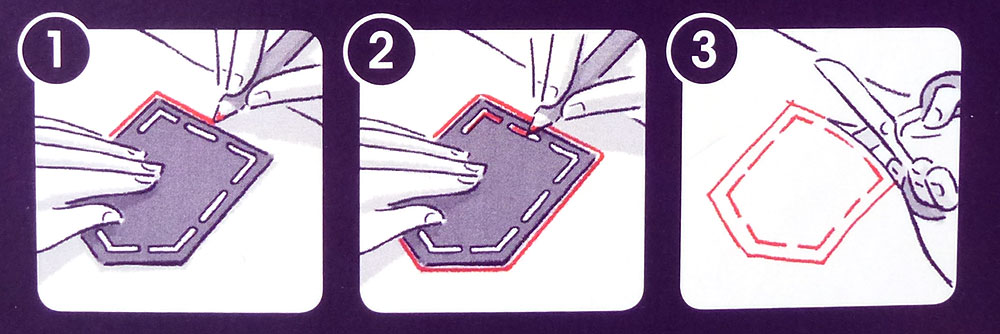

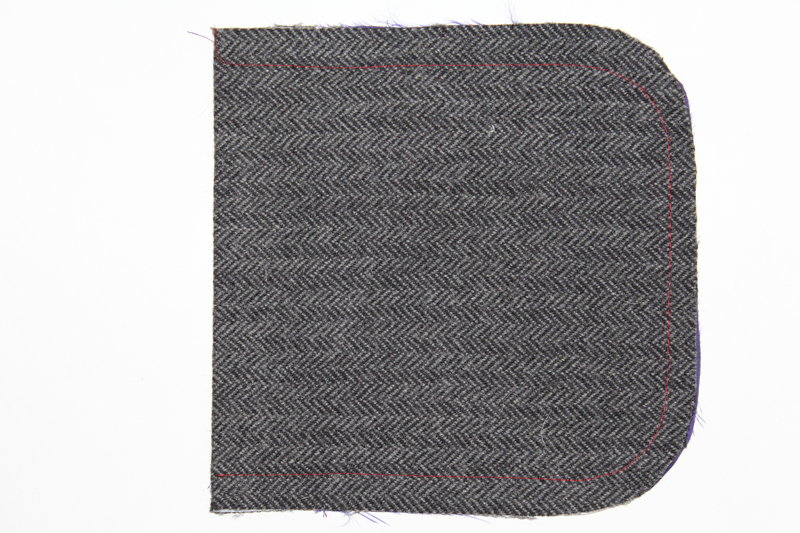

- We lay a stitch along the contour of the pocket. It is advisable to use bright threads.

- A little further (about 1 cm) we lay the second line, the thread is loosened.

- Fold the seam allowances to the wrong side and secure with pins.

- We hand-baste the hem along the second line.

- Remove the pins.

- Let's iron.

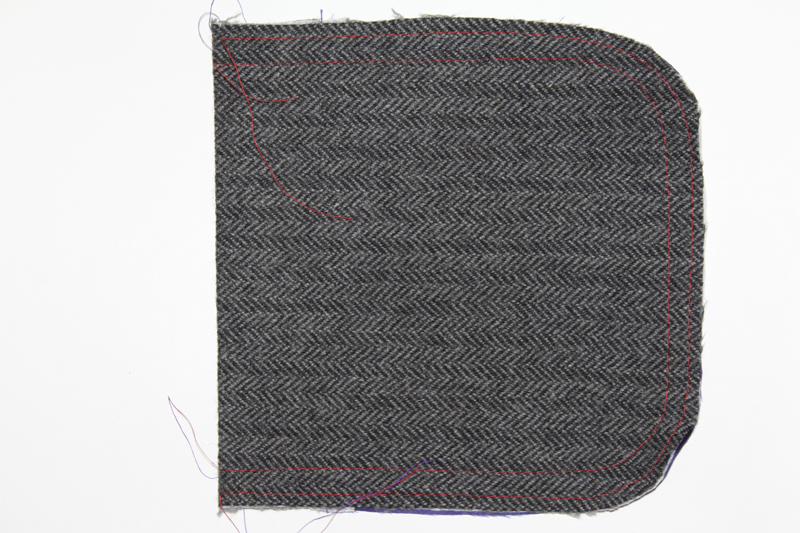

- We cut off the allowance to the running seam, so we have about 1 cm of total allowance left.

- Let's iron.

- Remove the original machine seam.

- We apply it to the main piece of clothing.

- We baste, then stitch. It is advisable to make fastenings at the entrance to the pocket.

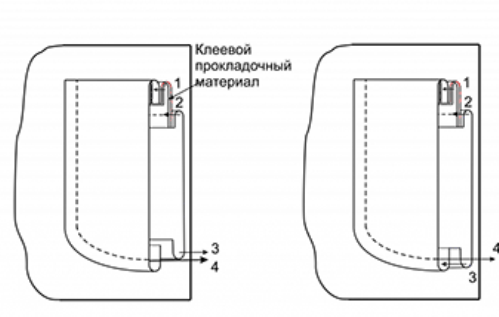

Patch pocket with stitched facing

Stages of work:

- We make patterns and cut out in the same way. But we do not take into account the height of the one-piece facing; along the upper edge we make the usual allowance of 1.5 cm.

- We cut out the stitching, its length is equal to the length of the main part, its width is 3–4 cm.

- We duplicate the upper edge of the main part with non-woven material.

- We duplicate the facing with non-woven fabric on the wrong side.

- We sew the facing to the main part “face to face”.

- Turn it inside out so that a small edge remains.

- Let's iron.

- Sew the pocket lining along the bottom edge.

- Iron the seams to the lining.

- We process the side and bottom edges as in the previous model.

- We sew our blank to the main product.

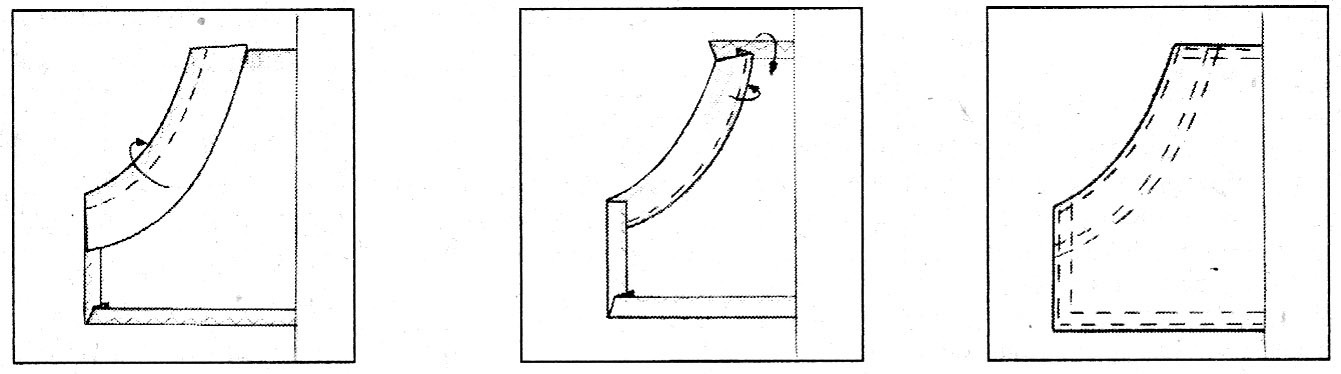

Patch pocket with slanted entry

The most commonly used options are famous "kangaroos":

- We determine the shape and size.

- We cut out the main part and facing, repeating the shape of the entrance to the pocket.

- We duplicate the facing and the main blank along the edge with non-woven material.

- We fold the facing and the main workpiece “face to face”.

- Secure with pins.

- We stitch it.

- We bend the facing to the wrong side.

- Iron it.

- If desired, we can do stitching.

- Iron the pocket allowances to the wrong side.

- We process similarly to the previous options.

- Sew to the main product.

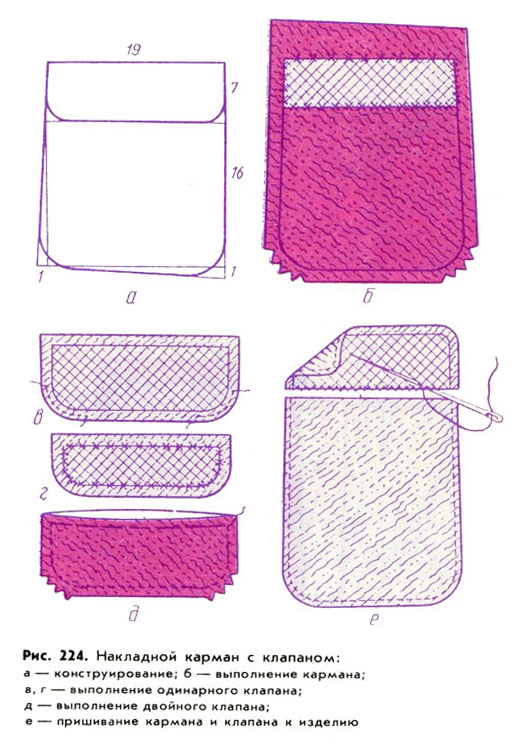

Valves

This type of finishing is complemented by any types of pockets, but they are most often used in patch pockets.

This type of finishing is complemented by any types of pockets, but they are most often used in patch pockets.

Valve parts are always cut out in duplicate: from the main fabric or main + lining.

The shape may vary. As a rule, the flap repeats or complements the main image of the pocket:

- Determine the shape and size of the valve.

- We cut out two parts.

- We put them face to face.

- Secure with pins.

- We stitch it.

- Iron and turn inside out.

- Let's iron again.

- We perform decorative stitching along the contour.

- Fold the allowances along the top edge inward and stitch.

- Sew over any type of finished pocket.

Pockets have long ceased to be just an auxiliary device, like sewn-on handbags. Modern clothing is unthinkable without them, so when sewing any type of clothing, we will not forget about pockets.

0

0