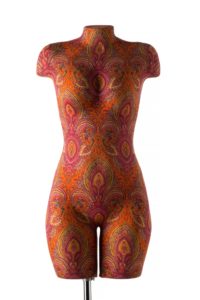

Each person is individual and body measurements do not always correspond to beauty standards. A woman always wants to look beautiful and stylish, regardless of age and with any figure. For a person who creates clothes, it is important to have an indoor mannequin, as it is one of the most important tools in the work.

Clothing that fits perfectly decorates a person, emphasizes the dignity of the figure and gives confidence. But numerous fittings are tiring and therefore it is convenient to have your own individual layout. There is no need to constantly distract a person to try on and adjust clothes. This is what our master class will be about: how to make a mannequin with your own hands at home. Some nuances should be taken into account: - work on the project begins in the morning.

Important. A child mannequin is made in the same way as an adult mannequin. Only as a model is a child.

The first method is using tape

To create the desired silhouette you will need:

- assistant;

- cling film (knitted dress or T-shirt);

- comfortable underwear (a bra that will be worn under tailored clothes);

- Scotch tape, any adhesive tape;

- a roll of padding polyester (old blanket, unnecessary things);

- 2–3 cylinders of construction foam;

- rubber gloves;

- newspaper.

And:

- several pairs of scissors (some may get stuck due to constant work with tape);

- rags (for wiping scissors);

- medium-long stick (for possible scratching);

- a stool (you can kneel when your legs are tired, but you must be very careful not to damage the base);

- water in large quantities, preferably with a straw (tube, for ease of consumption).

Work progress:

First stage

First, you should wrap the person whose parameters you need well with cling film (wear a tight-fitting T-shirt). We begin winding it from the bottom up. It should be taken into account that you need to make several layers, given that the fit should not be strong. The film has a shrinking function.

First, you should wrap the person whose parameters you need well with cling film (wear a tight-fitting T-shirt). We begin winding it from the bottom up. It should be taken into account that you need to make several layers, given that the fit should not be strong. The film has a shrinking function.

Cling film can reduce your proportions enough that you simply won’t fit into your sewn clothes. The edges of the film can be secured with tape.

Second phase

Then they are covered with tape. The strips of tape should be small, about 10-15 cm; long pieces are difficult to glue, they cling and stick out. Start from the chest around the circumference, the tape is glued from bottom to top with overlaps. This will ensure the breasts have the correct shape. Adhesive tape is applied in 2-3 layers in different directions. It is important not to forget to mark the waist and hem line.

Then they are covered with tape. The strips of tape should be small, about 10-15 cm; long pieces are difficult to glue, they cling and stick out. Start from the chest around the circumference, the tape is glued from bottom to top with overlaps. This will ensure the breasts have the correct shape. Adhesive tape is applied in 2-3 layers in different directions. It is important not to forget to mark the waist and hem line.

- the layer of tape should lie freely, from the waist first down, then up;

- the chest area is affected last to avoid prolonged difficulty breathing;

- It is imperative to collect the hair so that it does not touch the cocoon.

When the body is pasted to the required length, proceed to the next steps.

Third stage

After completely gluing with tape, you should align the bottom line, measuring from the floor. Next, mark the middle of the back, with marked transverse segments. According to these marks, the cocoon is cut and the bottom is trimmed.

After completely gluing with tape, you should align the bottom line, measuring from the floor. Next, mark the middle of the back, with marked transverse segments. According to these marks, the cocoon is cut and the bottom is trimmed.

The model needs to be released from this spacesuit, carefully cut along the back with scissors. Afterwards, glue the cut with tape.

Fourth stage

For the arms and neck, circles are cut out of thick cardboard (reels of tape). Place the cardboard and wrap it with tape.

Fifth stage

For convenience, so that you can hang the mannequin, a hanger is inserted into the neck, and cardboard is placed on top.

Sixth stage

The required mannequin is almost ready, all that remains is to fill the internal space. You can use padding polyester, but this will make the mannequin short-lived, as it will bend under the weight of the heavy fabric. Therefore, in order for the figure to last for a long time, we fill it with building materials: alabaster or foam. Each has its own advantages and disadvantages.

The required mannequin is almost ready, all that remains is to fill the internal space. You can use padding polyester, but this will make the mannequin short-lived, as it will bend under the weight of the heavy fabric. Therefore, in order for the figure to last for a long time, we fill it with building materials: alabaster or foam. Each has its own advantages and disadvantages.

But before you fill the inside, you need to prepare the bottom to cover the bottom of the mannequin. To do this, place the mannequin on a newspaper and cut out the desired shape. Using this pattern, the bottom is cut out on cardboard.

Fill 1/5th or 1/6th of the mannequin with foam, then fill it with newspaper, let the foam harden, then foam and newspaper again. Do this until the space is filled. Foam is an expensive building material, so newspaper is added.

Seventh stage

The final step for an aesthetic appearance would be to sew a cover from stretch knitwear, but first you should fit a mannequin thin padding polyester so that it is easy to stick needles and pins into it.

The final step for an aesthetic appearance would be to sew a cover from stretch knitwear, but first you should fit a mannequin thin padding polyester so that it is easy to stick needles and pins into it.

Here we have a ready-made version of an individual mannequin.The manufacturing method is quite simple and can be done by every craftswoman.

The disadvantage of this method is the cost of construction foam and the smell that is released during work. Therefore, it is better to use foam outdoors, in a well-ventilated area.

Tips for beginners on making mannequins from tape

Before wrapping, you should put on the underwear in which the clothes sewn on the mannequin will be worn. Not fitted mannequin It may turn out to be a size smaller than the model.

To create a mannequin, you need to understand what indicators need to be taken into account, that is, what we will wrap with film. This is waist size, shoulder width, back width, arm circumference, chest size, hip size. Measure these indicators so that you can compare them with the resulting dummy.

It will be more convenient to work with a mannequin if you make a soft base of batting under the fabric. It is made similarly to outer clothing. Seam allowances and darts are cut off.

It will be more convenient to work with a mannequin if you make a soft base of batting under the fabric. It is made similarly to outer clothing. Seam allowances and darts are cut off.

The tape should not be pulled too tight. During the wrapping process, a person must periodically bend slightly and raise his arms. Otherwise, it will be difficult for the model to breathe and the production of the mannequin shell from adhesive tape may not survive until the end.

Ideally, the height of the mannequin should correspond to the height of the person for whom it is made. In this case, the height of the heels must also be taken into account.

For greater strength, the top layer is made of reinforced construction tape. It will ensure rigidity of the form.

Finally, take a measuring tape and take measurements. If they match those that were made initially, then congratulations, you did everything perfectly.

The second way is using plaster

A pretty good option is to make it from gypsum.The method is more labor-intensive and time-consuming, but if performed correctly, the result will please you. There are, of course, a number of features that need to be taken into account:

A pretty good option is to make it from gypsum.The method is more labor-intensive and time-consuming, but if performed correctly, the result will please you. There are, of course, a number of features that need to be taken into account:

- It takes a relatively long time for the gypsum to fully set. Therefore, the model will have to stand absolutely still for about an hour. Since any movement can lead to deformation of the shape;

- the product itself is quite fragile, so it must be treated with the utmost care;

- and it is also necessary to take into account the fragility factor during transportation;

- the manufacturing procedure is carried out on a naked body, so it must be lubricated with cream or Vaseline to avoid skin irritation;

- It should be noted that if a mannequin is made for personal use, i.e., according to your body parameters, then it is impossible to cope with this task yourself. In this case, you will again need an assistant. Applying plaster material to the body requires care; it is very important that it is a person you will not be embarrassed about, since during the manufacturing process you will have to be naked.

What you need for making:

- assistant;

- comfortable underwear (a bra that will be worn under tailored clothes);

- Scotch tape, any adhesive tape;

- a roll of padding polyester (old blanket, unnecessary things);

- 2 kg of alabaster (3–4 cylinders of construction foam, plaster casts);

- rubber gloves;

- 5 rolls of medical bandage;

- Container in which bandages will be moistened;

- Directly plaster bandage;

- Matter or oilcloth that will be laid under your feet;

- Scissors or a knife to cut the plaster after hardening;

- Surface for drying the product.

And:

- several pairs of scissors (some may get stuck due to constant work with tape);

- rags (for wiping scissors);

- medium-long stick (for possible scratching);

- a stool (you can kneel when your legs are tired, but you must be very careful not to damage the base);

- water in large quantities (you will constantly want to drink), preferably with a straw (tube, for ease of consumption);

- Validol (possible loss of consciousness) Validol helps significantly.

Manufacturing process:

- First of all, it is necessary to provide a minimum set of clothing, this could be panties and a T-shirt, or a bra instead of a T-shirt in the case of making a female mannequin. In some cases, you can wrap the body with plastic film, but it should be noted that such a decision will slightly affect your figure, i.e. the shape will not fully reflect it in the future.

- Next, strips of plaster bandage are cut to a length of 5–10 centimeters, soaked and applied to the body. It is advisable to start with the chest and shoulders. Next, move smoothly down. It is necessary to carefully monitor the formation of the armhole and ensure that there are no air bubbles in it. The entire process should be carried out as quickly as possible, since the dressings will begin to dry immediately after contact with the skin. Apply 3-4 layers in this way. Remember, the entire coating must be perfectly smooth, so until it hardens, you must refrain from the temptation to turn, bend over, or even move in any way. If you still want to look at something, you can ask your assistant to bring a mirror. Particular attention should be paid to the bottom of the mannequin. Here, already at the initial stage, you should clearly decide: the form is performed with legs, or only the contour of the hips is needed.

- After completely covering the body with plaster, you must stand still for at least 30–40 minutes from the moment the last strip is applied.

- After the plaster has dried, the mold is carefully cut along the shoulders and armhole lines. It is necessary to work as carefully and concentratedly as possible so as not to injure the model. The wrapping process is carried out from top to bottom, there must be spacers inside the cocoon so that the cocoon does not lose its shape. The figure takes about two days to dry under normal room conditions. You should first leave room for a stand, for example, fix a stick in the figure so that there is a hole left for installing the model.

- The next step is to sew the two resulting parts together using threads, or you can also use plaster bandages, but reinforced tape is easier to work with. There must be spacers inside the cocoon so that the cocoon does not lose its shape.

- When the form is completely dry, take a control measurement to ensure it matches the contours of the model’s body.

- To give stability and rigidity, it is necessary to fill the mold. This can be done with any available material (foam rubber, pieces of fabric, paper, polyurethane foam).

The mannequin is almost ready

Important. When performing the work for the first time, the model may turn out to be slightly smaller than its size, then you can correct this error using papier-mâché. It should be noted that the drying time for a thin layer of paper is two days, and about four days for a thicker one.

The manufacture of the mannequin is completed by installing cardboard and a rod with a stand. The cardboard is placed perpendicular to the axis - the line of the spine. The edges are secured with tape. A pipe or stand is inserted through the prepared hole; the main thing is that it is on wheels and can be rolled along the floor.

The manufacture of the mannequin is completed by installing cardboard and a rod with a stand. The cardboard is placed perpendicular to the axis - the line of the spine. The edges are secured with tape. A pipe or stand is inserted through the prepared hole; the main thing is that it is on wheels and can be rolled along the floor.

The mannequin is covered with non-slip fabric. It could be:

- velvet;

- cashmere;

- thin drape;

- old wool blanket.

Everything is pre-cut according to the usual template of the required size, with allowances. It looks more beautiful if you make longitudinal darts from the armhole. Armholes are not cut out. The neck is made high and covered with a piece of fabric. Then the sour cream cover is put on the mannequin with the seams facing out and adjustments are made. Now you can sew the seams and dress up your mannequin.

Everything is pre-cut according to the usual template of the required size, with allowances. It looks more beautiful if you make longitudinal darts from the armhole. Armholes are not cut out. The neck is made high and covered with a piece of fabric. Then the sour cream cover is put on the mannequin with the seams facing out and adjustments are made. Now you can sew the seams and dress up your mannequin.

The pin cushion looks good on the neck and is comfortable to work with. The waist is indicated by a ribbon.

In addition to the fact that the mannequin serves as a ready-made sample for tailoring, it can also be used as an interior decor item. And also to iron things with steam when it is not possible to do it on an ironing board.

You can make a mannequin at home, you just need to spend your time and a little money. A mannequin made with your own hands will please the eye and serve for a long time.

Important. Such a mannequin is suitable as a tailor's mannequin for sewing clothes and as an individual mannequin based on its figure.

It's up to you to decide which method suits you best, the faster one made from adhesive tape or a plaster dummy mummy. We hope you enjoyed the master class and it helped solve the most important problem for craftswomen. New victories and achievements!

0

0