To take good quality photographs of jewelry you will need a mannequin. Then any decoration will be presented in a favorable light. Such a bust can be bought in a store. But it’s better to make a mannequin for jewelry with your own hands. You can decorate it to your own taste, so that the background matches perfectly with the stand in the photo.

Classic bust for jewelry

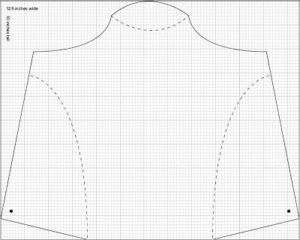

The simplest option would be making a bust from cardboard. To make it, you will need to apply a pattern to graph paper, an example of which is shown in the photo. The broken line in the figure shows the fold lines, and the solid line shows the main contours.

The simplest option would be making a bust from cardboard. To make it, you will need to apply a pattern to graph paper, an example of which is shown in the photo. The broken line in the figure shows the fold lines, and the solid line shows the main contours.

To make the mannequin more attractive, you can cover it with fabric or cover it with textured paper. Next, you need to bend the template in the right places and make small holes in the lower corners. An elastic band is pulled through the holes, thanks to which the edges of the bust are fixed to each other and the mannequin can be installed on any surface.

By making it simple DIY jewelry mannequin, you can move on to more complex masterpieces. Another version of the stand will require much more effort to manufacture, but the result will be appropriate.

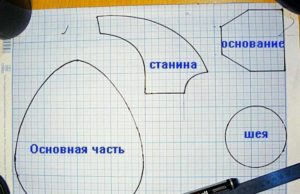

To begin, as in the first case, you need to start creating your mannequin with a pattern, a sample of which is shown in the photo. It should be redrawn on special paper or simply printed on a printer in the required format.

To begin, as in the first case, you need to start creating your mannequin with a pattern, a sample of which is shown in the photo. It should be redrawn on special paper or simply printed on a printer in the required format.

The next step is choosing the material for each part. The bed and base will bear the main weight and load, which means the material from which they will be made must be quite durable. Among other things, screws will be needed to secure the elements, which should also be taken into account when choosing the material. As practice shows, the best option would be wood, drywall and other options with similar characteristics.

Selection of materials and connection of load-bearing elements

For the neck, you can use plastic, hardboard, or several layers of cardboard glued together. As for the main part, it must be durable, but at the same time remain flexible. It is best to make it from elastic plastic or from several layers of cardboard.

In addition to the elements drawn on the pattern, to create a mannequin you will need a small circle for the neck and a backing for the base, which can be made from two layers of cardboard.

Next stage – selection of material for finishing the base and frame. Of course, the simplest option is painting, but practice shows that it is best to decorate these elements with fabric, artificial or natural leather. Particular attention should be paid to the choice of glue, namely drying time and elastic properties.

Now, the elements can be connected to each other.To do this, strictly in the center of the base, you need to draw a line along which the screws will be screwed into the frame. To prevent the fixing elements from protruding above the surface, you can make small recesses for them.

When the base is securely connected to the frame, you should begin finishing. The sides and ends of the frame, as well as the upper part of the base, are glued with the material selected in advance.

Assembly and finishing of the main part

The next step is to assemble the main part. Layers of cardboard or elastic plastic glued together in advance are given a slightly curved shape, repeating the bend of the end of the frame. A vertical line is drawn in the center of the workpiece, along the edges and in the center of which small recesses are made for the screw heads. Now the main part can be screwed to the frame.

At this point, the difficult part of the work is almost completed, but the mannequin still lacks a neck. To create it, you will need a small tube, 5-6 cm high. You can make it yourself from cardboard, or take the core from adhesive tape or toilet paper. Using glue, the tube is fixed to the main part. It should be located along the center line 2.5 cm from the top. The top of the tube is closed with a pre-prepared circle made of hardboard or plastic. To fix these elements, you can use any quick-drying glue.

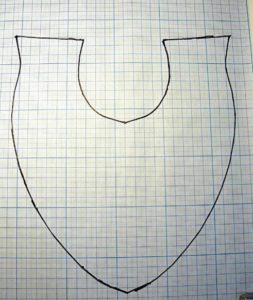

Now, the only thing left to use for decoration is tighten material. Velvet, thin natural or artificial leather, and velvet are perfect for this. A sample of the pattern itself is shown in the photo.

Now, the only thing left to use for decoration is tighten material. Velvet, thin natural or artificial leather, and velvet are perfect for this. A sample of the pattern itself is shown in the photo.

When transferring a design to fabric, it is recommended to add approximately 1.5 cm to the seam allowance on each side. When everything is ready, the back seam can be sewn, after which it should be carefully ironed and topstitched.

Before you begin to stretch the fabric, the allowances, the edges of the mannequin’s neck, as well as the bottom of the main part are coated with glue. After this, you can begin the stretching process. The back seam is centered first. It should be positioned clearly in the center, and only then evenly stretch the rest of the fabric.

You can decorate the upper part of the neck using foam rubber, plastic or other material, which is also covered with the selected fabric. The main part on the reverse side is easily decorated using cardboard. It will not only give the mannequin a finished look, but will also make the edges of the finishing fabric invisible. The base can be closed in the same way.

Detailed approach to manufacturing

Making a stand

The steps described in detail will give you the opportunity to make your own stand.

For this you need:

- graph paper for pattern (pattern);

- cardboard;

- Chipboard or drywall;

- screws;

- fabric or leather for finishing;

- PVA glue or super glue;

- ruler;

- scissors;

- needle.

Mannequin pattern for jewelry

First, patterns are made of all the parts you need. It is recommended to do this on graph paper. If you don't want to draw them yourself, you can find ready-made ones and print them out.

Cutting out parts

The main load of the mannequin falls on the frame and base; it is on them that everything rests. Therefore, the material from which you are going to make them must be dense, at least a centimeter thick. For example, you can take chipboard or drywall. You will have to screw screws or nails into the material you choose, which it must withstand. It is worth noting that removing the screws if you place them incorrectly is much faster and easier than removing the nails. Plastic is suitable for the neck.It can be replaced with thick cardboard, glued in 5 layers.

Cutting out the main part.

As already noted, several layers of cardboard should be glued together. Choose cardboard that is not only high-density, but also flexible enough that you can bend it without breaking it. Just cut out the base according to the pattern.

Finishing the base and bed

Of course, the easiest way would be to just paint the parts. But if the material from which they are made constantly crumbles, the paint should be replaced with fabric or leather. Do not use water-based glue, it may warp the cardboard and increase the time needed to create the mannequin.

Assembling the bed

The frame should be screwed to the base using several screws. This should be done along the midline. Thick screws can damage the frame and it will begin to crumble. At the same time, they must be long, then the structure will be durable. The bed is glued on the sides. Only the lower part of the base and the area where it connects to the base should be left. These areas must be open.

Assembly of the main part

The first layer of base should be curved. You can give a similar shape using the edge of the table. In this form, the first layer is glued to the end of the frame. Repeat the procedure layer by layer. You can first assemble the base, and only then glue it. When the base is ready, screw it to the frame with several screws. Clean up any irregularities with sandpaper.

Construction of the tube

The required height of the product is 5 cm. To build a tube, simply take a long strip of cardboard. Attach the constructed product to the base of the mannequin, stepping back 2.5 cm from the top edge. Continue doing everything along the midline. A hardboard circle is attached to the top of the tube.

Details for fitting

It is also recommended to make patterns in advance. To fit a mannequin Thick knitwear, leather or leatherette are suitable, but they must be thin. Start cutting out the necessary parts from the selected material. Don't forget to allow an allowance of a few centimeters. Sew the back seam using a sewing machine. Please note that if using leather, it requires a special needle. Afterwards the seam should be ironed and stitched.

Tightening a mannequin

Apply glue to the remaining allowances and begin to pull the material onto the product. The seam running along the back of the head must be firmly secured on all sides. Check that it is exactly in the middle. Glue the material in some areas and start tightening. Do this until the surface is completely smooth and even, there should be no wrinkles, etc. Before starting this procedure, be sure to make sure that the mannequin itself is free of debris and dust.

Neck and base

Take a circle that will later serve as a neck and glue the material of your choice to it, on one side. It's better if it's thin. Cover the top with the selected material and glue the edges from the wrong side. Using glue, secure the circle to the neck of the product. You can also cover the base substrate with the selected material, but you may not do this at your own discretion. Connect this part to the mannequin. If necessary, you can seal the end of the base with a strip of the selected material.

Now you have your mannequin. It is quite simple to build, although it will take quite some time. A do-it-yourself jewelry mannequin is made using many materials and details. Therefore, make sure that you have everything you need at hand before starting work.

This video will also be useful:

0

0

Hello, great article!