Dummies in sports are designed to strengthen muscles, practice punches, increase endurance, etc. A wooden exercise machine that imitates an opponent, used at home. It’s not difficult to do it yourself; it requires tools and effort.

Dummies in sports are designed to strengthen muscles, practice punches, increase endurance, etc. A wooden exercise machine that imitates an opponent, used at home. It’s not difficult to do it yourself; it requires tools and effort.

Selecting quality wood

For a mannequin, you need to choose good material. This will ensure that the finished simulator will not crack, swell, or parts at the joints will diverge.

Wood from different tree species has different properties, depending on the following:

Wood from different tree species has different properties, depending on the following:

- Texture – formed from layers of wood, clearly visible on the cut of the trunk. Affects the quality of processing and the exterior of the finished training mannequin.

- The core is the central part of the frame, strong. Not every trunk has it.

- Sapwood is the wood around the core. Before use in the production of simulators, it requires drying because it contains a lot of moisture.

The most suitable tree species for making mannequins, growing in Russia:

- Oak has a beautiful texture. Strong solid material. Resistant to rotting. It has a heartwood separated from the sapwood, which significantly reduces the quality of the wood. Oak without rot costs about 4 times more. Such logs and boards are prone to cracking and therefore require careful drying. In the building materials market, bog oak is the most valued - dark-colored wood soaked in water. Very expensive and rare material.

- Pine – the most used tree species. Stronger in the direction of the fibers, but susceptible to cracking in other directions. Difficult to paint, does not etch. There is a core in the center. Rot resistant.

- Ash – has a core with an indistinct transition into sapwood. For the spring parts of training mannequins, the ideal option is high strength and flexibility. Used in the production of oars and bows.

- Maple - a tree without a core. Maple wood has many knots and requires careful processing. Strength and elasticity are lower than those of ash. Easy to process.

- Birch and poplar are sapwood species and do not contain a core. They do not have sufficient strength. Therefore, such wood should be used with caution; it is not suitable for all parts of the mannequin.

The most suitable types of trees for making a figure for training with your own hands are oak and ash. You can use maple, but the choice must be approached with special care. Some components, not requiring endurance under heavy load, can be performed from birch, pine and poplar.

Preparation of material

For the base of the product (“body”) you will need dry wood. A simple, but at the same time expensive method is to buy a rounded log.Industrially dried wood contains no more than 12% moisture and is ideal for further processing.

You can save moneyby drying the material with your own hands. To do this, the selected log is placed under a canopy or in the attic at a height of 0.5-1 meters from the floor. The room should be well ventilated. Air flowing around the workpiece from all sides, dries the log to a moisture content of 15-18%. Depending on the quality of the material, the degree of ventilationThe process will take from six months to several years.

The danger of drying wood for a dummy yourself is that cracks appear at the ends of the workpiece. If you cover it with chalk or oil paint, cracking can be avoided.

Make sure that the workpiece is not exposed to sunlight or raindrops.

Home craftsmen suggest drying wooden raw materials using:

- Cement floor. Cement absorbs moisture, taking it from the wood. The workpiece must be constantly turned over and the material adhered tightly to the floor.

- Wood shavings. Wood will crack less if it is kept in dry sawdust or soil.

Training dummies: types and manufacture

Divided into two groups:

- Imitating individual parts of the human body;

- Similar to an opponent (humanoid).

The first category includes a wooden mannequin - makiwara. The simulator trains you to practice direct strikes and teaches you how to withdraw your hand after an interaction. Increases the technicality of attacks, increases strength and endurance.

Making a makiwara (wooden mannequin) is easy. For the wall version, you need to take two strong but elastic boards. Ash will do. At one end, a rectangular block is placed between the boards. On the other side, a piece of felt or other soft material is glued. Ready.The structure is nailed and tied to the wall. For additional reinforcement, place another board on each side.

You can make a human-sized wooden makiwara mannequin. Take a log with a diameter of 7 to 15 cm. The upper part is wrapped with twine, the bottom is dug into the ground or strengthened with tincture if it is intended to be used at home.

You can make a human-sized wooden makiwara mannequin. Take a log with a diameter of 7 to 15 cm. The upper part is wrapped with twine, the bottom is dug into the ground or strengthened with tincture if it is intended to be used at home.

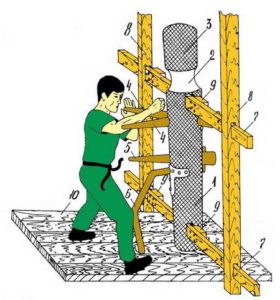

Used as a humanoid wooden figure for training wing chun mannequin. Imitates a human torso. Most often it contains three “arms” and one “leg”. It can be stable, mounted on a spring or on a rotating platform. Each athlete has his own individual mannequin. Wing Chun, maintaining the following proportions:

Used as a humanoid wooden figure for training wing chun mannequin. Imitates a human torso. Most often it contains three “arms” and one “leg”. It can be stable, mounted on a spring or on a rotating platform. Each athlete has his own individual mannequin. Wing Chun, maintaining the following proportions:

- With the knees bent, the middle “arm” of the figure is directed to the navel, and the upper ones to the middle between the point of the shoulder and the armpit.

- The two “arms” are located in the same plane. When drilling (hollowing out) holes for them, inside the “body” they will definitely intersect.

- The length of the “arms” of the simulator is measured along the part of yours, from the knuckles of the palm clenched into a fist to the elbow.

For the “body” of the simulator, a strong log is taken. Excess wood is removed from it. Using a plane and a pattern (you can cut out a circle of the required diameter in cardboard and constantly try it on the workpiece) a cylindrical shape is given.

The “body” is sanded: first with coarse-grain sandpaper (no more than 60), then with fine-grain sandpaper (100 or more).

The mannequin's arms can be of different shapes and can be attached in different ways: using an internal or external spring, a wedge or a rubber band. Additional fastenings help to move in different planes.

The holes for the “arms” and “legs” of the simulator can be hollowed out manually with a chisel or drilled with a tool.You cannot make parts from cuttings for gardening tools; they break quickly.

The holes for the “arms” and “legs” of the simulator can be hollowed out manually with a chisel or drilled with a tool.You cannot make parts from cuttings for gardening tools; they break quickly.

Depending on the desired configuration of the figure’s leg (the degree of bend at the “knee”), the material is selected. It can be made not only from wood, but also from metal (for decoration it is wrapped with rope).

All parts of the mannequin are sanded, treated with stain, and varnished.

After assembly, the training product is secured against the wall.

0

0