Leatherette – a leather substitute, is one of the most popular materials. The material is most widely used in construction and decoration.

Leatherette – a leather substitute, is one of the most popular materials. The material is most widely used in construction and decoration.

The high demand for leatherette is justified by the following characteristics:

- Frost resistance. The material performs its functions well even at sub-zero temperatures. It also helps retain heat in the house, so it can be used on entrance doors;

- Durability. The material retains its properties from 7 to 10 years;

- Water resistance. The material has moisture-resistant properties, which prevents damage to the product or insulation;

- Soundproofing. The material can be used for the entrance door, since noise will not penetrate into the room through the canvas;

- Easy to care for. To preserve the appearance of leatherette, wiping with a damp cloth is sufficient. You can use a special cream that will add shine to the leatherette;

- Antiseptic properties. Resistant to bacterial rot, mold and other pests;

- Resistance to aggressive chemical environments. The material can be washed with any household chemicals;

- Low cost. Upholstery with leatherette is affordable for the average family;

- Wide range of textures and colors.

Instructions - trim with dermantine

In the process of upholstering a product, you need to adhere to a certain technology. It will allow you to make maximum use of the beneficial properties of the material and ensure a long service life. The procedure includes the following steps:

In the process of upholstering a product, you need to adhere to a certain technology. It will allow you to make maximum use of the beneficial properties of the material and ensure a long service life. The procedure includes the following steps:

- surface preparation;

- upholstery with insulation;

- leatherette upholstery;

- decor with accessories.

Each stage has its own nuances, so you need to carefully familiarize yourself with the specifics of performing the listed points.

Preparation

If the casing is being replaced, you need to stock up on a knife, pliers and, if necessary, a screwdriver. The procedure is as follows:

- Remove from hinges.

- Dismantling of fittings.

- Using pliers, all decorative nails are removed.

- Leatherette and insulation are removed. Removing the insulation may take some time if it was attached to the metal door with glue.

- The surface is prepared for covering.

If the door was not previously chipped, then all the fittings are simply removed. It is necessary to remove all elements that stick out on the surface. There should be a flat surface underneath the leatherette, so you can level the relief using a slab of plywood. It can be secured with ordinary nails. It is important not to forget to treat the wood with special products.

Insulation

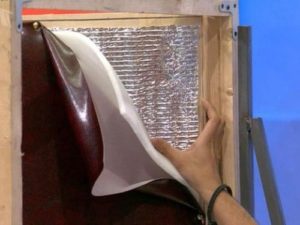

First you need to decide on the insulation material. The most suitable for leatherette are:

First you need to decide on the insulation material. The most suitable for leatherette are:

- Foam rubber. Low price, wide range of densities and thicknesses. Has a service life equal to leatherette. Has average insulating properties;

- Batting. Inexpensive material with a service life of up to 30 years.However, over time it dents and can absorb moisture. It is toxic when burned;

- Izolon (a subtype of polyethylene foam). The most modern option. Has good insulating properties. The most expensive of all materials, but the final cost will not be too high.

The insulation is secured to the wooden surface using a stapler. On the outside, you need to retreat up to 8 cm from the edges. Insulation is applied to the entire area, without indentation. Markings are applied for working with a stapler or driving nails. The step between staples or nails should be 10–15 cm. Treatment is carried out along the entire perimeter.

For a metal surface you need glue, which is also applied around the perimeter, up to 8 cm from the edges. Don't forget to cut off the insulation on the handle, lock and peephole.

Preparation of tools and accessories

To use your time efficiently, before upholstery you need to acquire a set of necessary tools. The set includes:

- hammer;

- stationery knife and, if necessary, scissors;

- stapler (if not, use a hammer);

- roulette;

- marker;

- brushes (for metal surfaces).

The list of tools and materials for wooden and metal doors is slightly different. Therefore, each material has its own cladding technology. It is also important to acquire all the materials at once:

- leatherette;

- insulation;

- staples or nails (wooden surface);

- glue (metal);

- decorative nails;

- braid (in case you need to additionally fix the leatherette and decorate the door).

Reference! Choosing decorative nails according to design is not difficult, since the market is overflowing with products of different shapes, sizes and colors.

Upholstery technology

Working together will go much faster. A second person will help stretch the fabric for comfort and evenness of the relief. The edges of the fabric are always bent inward, which will make the upholstery durable and aesthetically pleasing. The folds should be a few centimeters wide. The wooden door is covered with nails with a decorative cap. Step from 10 to 15 cm.

Working together will go much faster. A second person will help stretch the fabric for comfort and evenness of the relief. The edges of the fabric are always bent inward, which will make the upholstery durable and aesthetically pleasing. The folds should be a few centimeters wide. The wooden door is covered with nails with a decorative cap. Step from 10 to 15 cm.

Important! You need to make sure that the insulating rollers do not peek out from the gates.

Leatherette should not cover the door to the very edges. A few millimeters need to be retreated to ensure free movement.

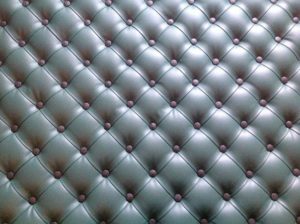

Curly decoration using decorative nails is often used. Soft insulation allows you to create a relief on the surface, which will completely transform the door. Be sure to use a marker to mark the locations for installing accessories. Next, nails are hammered into the designated places, which usually have a removable decorative cap so as not to damage it during installation.

There are a large number of patterns that can be created on the surface: from simple dots to geometric shapes such as rhombuses and squares. On the Internet you can find many patterns for decorating with furniture nails. You can stretch a decorative thread between the nails, which will change the pattern and relief.

For a metal door, you need to come up with a design at the preparation stage in order to secure the bases of the screw buttons with glue. Small holes for screw buttons are made in advance in the insulation and leatherette.

Upholstery of a wooden door: video

Upholstery has its own nuances. Wood needs care and protection. Therefore, wooden doors often have an unpresentable appearance. A good restoration option is leatherette upholstery. The tree must be treated with an antiseptic.When working with a wooden panel, the lining must be secured using a stapler. Since the iron surface requires glue, it is much easier to staple wood. Furniture nails are used on the edges.

To be able to decorate the doors correctly, you must follow the instructions given in the video.

How to cover a metal door with leatherette?

A metal door is usually placed at the entrance, so it is extremely it is important to use high-quality insulation. Often only the inside is insulated, but a range of decorative accessories allows you to decorate the outside using insulation.

A metal door is usually placed at the entrance, so it is extremely it is important to use high-quality insulation. Often only the inside is insulated, but a range of decorative accessories allows you to decorate the outside using insulation.

A metal door does not require insulation beads on the outside. The size of the insulation should be 1–2 cm smaller at the edges of the surface area. You need to take a piece of leatherette that is 5–6 cm larger at the edges than the area of the door. This is necessary for bending. The upholstery process consists of the following steps:

- Glue is applied around the perimeter, retreating up to 2 cm, and in thin strips over the area.

- Insulation is applied and pressed for a while. The drying time for the glue is indicated on the packaging.

- Starting from the top, glue is applied to the back of the product at a distance of 5 cm from the edge. Press the leatherette until the glue sets.

- The same procedure is carried out on the lateral edges. It is important to stretch the fabric to a uniform relief. Sometimes you have to cut off extra pieces that will prevent the door from closing.

Upholstery on the inside

The inside of the front door can be insulated with polystyrene foam. Thus, it will also be possible to simplify the procedure for upholstery with leatherette. The insulation process is as follows:

The inside of the front door can be insulated with polystyrene foam. Thus, it will also be possible to simplify the procedure for upholstery with leatherette. The insulation process is as follows:

- A frame under the foam is fixed over the area of the door.For this purpose, planks having the thickness of polystyrene foam boards are used. The slats are fixed using metal screws, which are fixed into pre-drilled holes.

- All large seams and joints are sealed with polyurethane foam.

- Foam boards are installed in the frame, which are fixed with special glue. The gaps between the plates and slats are also sealed with polyurethane foam.

- A sheet of plywood, equal to the area of the door, is nailed to the slats.

- The further procedure is similar to upholstery of wooden products. It is only important to ensure that the decorative nails are nailed to the location of the slats.

On the inside, insulating rollers are attached to the door frame. They should be placed flush with leatherette on the hinge side. On the back and top the protrusion should be up to 5 mm. From below, the roller is located at a height of 1.5–2 cm from the floor.

Tips, recommendations and what to pay attention to

When choosing a material for upholstery, it is important to remember the disadvantages of leatherette:

When choosing a material for upholstery, it is important to remember the disadvantages of leatherette:

- Low fire safety. A highly flammable material that emits acrid smoke when burned;

- Not the most durable material, which is easily scratched and cut;

- In case of mechanical damage, it will not be possible to return to its previous appearance.

There are also important points to consider when choosing leatherette:

- The material must be elastic. The hardness of leatherette indicates a fake;

- Choose a coarser fabric;

- A pungent odor indicates poor quality of the fabric.

When upholstering with leatherette, it is important to maintain the consistency of the process and take into account the characteristics of the materials used. If the technology is not broken, then such upholstery will last up to 10 years.

1

1