Recently, the demand for genuine leather products has not been so strong. The reason is the emergence of less expensive, high-quality products made from eco-leather. The popularity of this material is explained by its differences for the better from other types of artificial material.

What is the difference between eco leather and artificial leather?

Eco leather - a high-tech material that allows you to create wear-resistant products at affordable prices. Ecological leather is in demand in such industries as:

Eco leather - a high-tech material that allows you to create wear-resistant products at affordable prices. Ecological leather is in demand in such industries as:

- Furniture: production of upholstery for armchairs and sofas.

- Haberdashery: creating bags and wallets, briefcases and purses.

- Light: tailoring.

Many companies use eco-leather to produce car seat covers.

Artificially produced leather consists of the following layers:

- basics;

- impregnating composition;

- polymer coating.

The fabric base of the eco-material is made of natural or polyester materials.

The polymer coating of the eco-material is polyurethane. There are other types of artificial leather based on the following polymers:

- PVC;

- polyacetal;

- thermoplastic elastomer;

- cellulose nitrate;

- rubber.

The structure and structure of ecological leather is porous. Other types of artificial material may have the following structure and structure:

The structure and structure of ecological leather is porous. Other types of artificial material may have the following structure and structure:

- monolithic and porous-monolithic;

- single-layer and multi-layer;

- baseless on a fibrous basis;

- reinforced.

Depending on the conditions under which artificial leather is used, such varieties are known as: regular and frost-resistant, acid- and alkali-resistant, water-resistant, etc.

Eco-leather is so close in some properties to natural leather that sometimes only specialists can distinguish them. This applies to the case where the polyurethane substitute material is of very good quality.

How to distinguish leather from eco-leather

If a person decides to purchase something made from natural material, he should be careful not to make a mistake. After all, unscrupulous sellers may offer polyurethane leather instead of natural leather.

If a person decides to purchase something made from natural material, he should be careful not to make a mistake. After all, unscrupulous sellers may offer polyurethane leather instead of natural leather.

It is necessary to take into account a number of features that eco-leather has:

- It heats up just like natural material, from human heat upon contact with it. Leaves no traces of moisture.

- The design on the front side is very close to the natural design.

- Not subject to significant deformation: when stretched, it quickly restores its shape. The fabric feels soft and stretchy to the touch.

- Absorbs moisture well.

How to distinguish leather from eco-leather on a jacket

The first thing you should do is find the label on the jacket where the sign is indicated. If the sign is in the shape of a diamond, it is a product made from environmentally friendly material. If there is no label on the product, you need to find the raw edge and take a good look at it.

The first thing you should do is find the label on the jacket where the sign is indicated. If the sign is in the shape of a diamond, it is a product made from environmentally friendly material. If there is no label on the product, you need to find the raw edge and take a good look at it.

Natural material will not delaminate. But if the cut reveals a top coating in the form of a film, and on the bottom layer there is fabric, it is polyurethane leather. If you cannot find the raw edge of the product, pay attention to the seams.

A leatherette jacket usually has closed seams and is very thin to the touch. A product made of natural material may also have closed seams, but when you feel them between your fingers, a “roller” is felt.

A jacket made of natural material will have a specific leather smell. So you can just smell the thing. But some manufacturers resort to tricks, impregnating leatherette with special aromatic solutions - they do not recommend completely relying on such experience.

The weight of the jacket also matters - things made of leatherette are usually light.

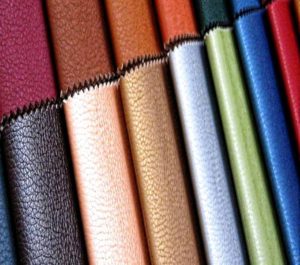

Eco-leather products have rich shades. This is because the dye adheres better to the polyurethane coating, therefore the colors look brighter.

Testing a piece of material with fire is an unreliable method, since special additives are added to modern leather substitutes.

A dubious method of checking authenticity is also exposing the material to water. Leather is known to absorb water, but if the surface of the product is treated with a water-repellent compound, the test result will be incorrect.

It would be much easier to distinguish leather from ordinary leatherette. The reason is that the properties of other types of artificial leather differ significantly from the properties of polyurethane and natural leather for the worse.

What is the difference between eco-leather and leatherette

No plasticizer additives are used in the production of eco-leather.Another feature in the production of ecological leather is a special attitude towards the base of the polyurethane film: the material does not experience various types of loads.

No plasticizer additives are used in the production of eco-leather.Another feature in the production of ecological leather is a special attitude towards the base of the polyurethane film: the material does not experience various types of loads.

The result is that eco-raw materials acquire a flexible structure and elasticity. Polyurethane film occupies no more than 25% of the total mass. Therefore, we can safely say that eco-leather is a fabric impregnated with polyurethane. And for leatherette you can choose a definition: a sheet of polymer reinforced with fabric.

The breathability of eco-leather is significantly higher than that of other leatherettes. This was achieved due to the fact that during the film application process, pores are formed through which air and water vapor pass, but not the water itself. The polyurethane network is very mobile, so polymers can rearrange under the influence of mechanical loads and temperature changes. These abilities explain their resistance to wear and very low temperatures. The polymers of films of other types of artificial leather wear out faster and crack in severe frosts.

Reference! Polyurethanes can even eliminate damage to the polymer network during deformation due to the presence of special groups of atoms that natural leather has.

What is the difference between eco-leather and leatherette?

The leatherette base is made of cotton fabric. The coating of this type of artificial leather is cellulose nitrate, which can be applied not only to one side of the fabric, like eco-leather, but also to both sides.

The leatherette base is made of cotton fabric. The coating of this type of artificial leather is cellulose nitrate, which can be applied not only to one side of the fabric, like eco-leather, but also to both sides.

Unlike ecological leather, leatherette has the following features:

- Easily wears out. The wear process can only be stopped if the new product is treated with silicone-based varnish.

- Does not tolerate low temperatures: cracks in the cold.

- Easily flammable and burns quickly. In fire hazardous areas it is not permissible to decorate furniture and doors with leatherette.

- When burning, an unpleasant smell of rubber is released. Substances released during combustion are very toxic.

- Shows resistance to moisture: prevents water from penetrating into the lining material.

- Leatherette can be easily damaged without much effort.

- Changes color when bent.

- Has low thermal conductivity. Leatherette items are cold to the touch. Even if you hold them in your hands for a long time, they hardly heat up.

- The top layer pattern is uniform, only vaguely reminiscent of the pattern of natural porosity.

- Mainly used as a finishing material.

- It gets tougher over time.

- It is sensitive to ultraviolet rays. It is better to cover the door with leatherette from the inside.

- Does not allow air to pass through. A person is clearly uncomfortable in clothes and shoes made of leatherette. It is highly undesirable to purchase such products, only in case of a shortage of funds.

What is the difference between Alcantara and eco-leather?

Among modern materials, Alcantara has recently become very popular. Many car enthusiasts are interested in having the car interior covered with this unique fabric that imitates natural suede.

Among modern materials, Alcantara has recently become very popular. Many car enthusiasts are interested in having the car interior covered with this unique fabric that imitates natural suede.

This artificial suede is produced using an advanced spinning method. The result is a very thin fiber, which is then pierced and impregnated with an adhesive composition. The inner surface of the woven material is treated with abrasive. As a result, the pile rises and the fabric becomes soft and silky.

Differences between Alcantara and eco-leather:

- More susceptible to contamination due to the presence of small fibers on the surface.

- Heats up less under the sun's rays.

- More pleasant to the touch.

- Requires more careful care. If staining liquids get on the surface, you have to wash the fabric.

- More elastic. Alcatara car seat covers can be easily applied to the seats. But if eco-leather covers are not tightened correctly, then over time cracks appear in the material.

- Products made from Alcatara are more expensive than those made from eco-leather.

It is impossible to say for sure who is more susceptible to wear and tear of Alcantara or eco-leather - it all depends on how well they were made.

Information about eco-leather is increasingly convincing that this is the material of the future - absolutely safe for humans during operation, reliable and high-quality raw materials.

0

0