Despite the abundance of goods made from genuine leather, their artificial substitute is no less popular among men and women. Manufacturers offer a wide range of bags, shoes and clothing of various colors and qualities.

Despite the abundance of goods made from genuine leather, their artificial substitute is no less popular among men and women. Manufacturers offer a wide range of bags, shoes and clothing of various colors and qualities.

Definition of artificial leather

Leatherette is a polymer material used instead of genuine leather. Examples of leatherette are: leatherette, polyvinyl chloride, tarpaulin, polyurethane, etc.

What is it made of?

There are several manufacturing technologies. The simplest method is considered to be the direct and calender method., when a coating and texture pattern are applied to the base.

There are several manufacturing technologies. The simplest method is considered to be the direct and calender method., when a coating and texture pattern are applied to the base.

A more complex technique is used to make artificial leather using the portable method. Here, layers of vinyl are applied to a preparatory paper base that has a relief structure, and then a textile backing.

Next, the paper web is removed from the workpiece and placed in a special drying machine, where all layers are finally bonded together.

Reference! Other production methods are also used: lamination and lamination.

How to do it yourself?

Selection of base (fleecy part)

The inner layer of leatherette determines the characteristics of the future product. When choosing clothes, shoes or accessories, you should pay attention to the reverse surface of the product.

The inner layer of leatherette determines the characteristics of the future product. When choosing clothes, shoes or accessories, you should pay attention to the reverse surface of the product.

Knitwear

Leatherettes made on a knitted backing are stretchable and at the same time durable. They have heat-protective properties. This artificial leather is often used in the manufacture of gloves or outerwear.

Textile

To produce fabric-based leatherette, durable and dense materials are used. They are quite expensive and have low elongation. During the production process, there is a possible risk of defects, which affect the quality of the product during wear.

Non-woven base

This fabric, like fabrics, contains threads. Only they are not intertwined with each other, but are connected with special protective impregnations. This fabric is most often used in the manufacture of leatherette.

Paper

Such a material will have low strength, lack of elongation and high wetness.

Selection of the top polymer layer (depending on the purpose of the skin)

Among leatherette products, there are abbreviations in the form of “PU” (polyurethane) and “PVC” (polyvinyl chloride). The structure and mechanical properties of the material directly depend on the type of polymers used to create leatherette.

Among leatherette products, there are abbreviations in the form of “PU” (polyurethane) and “PVC” (polyvinyl chloride). The structure and mechanical properties of the material directly depend on the type of polymers used to create leatherette.

Polyurethane (PU)

This polymer gives the product strength characteristics and increased ductility. PU is highly resistant to high and low temperatures, as well as hygroscopic.

It is very difficult to distinguish polyurethane from other non-natural materials.Externally, PU is very similar to genuine leather and has no odor, unlike PVC.

Polyvinyl chloride

Obtained as a result of the synthesis of vinyl chloride. It is not hygroscopic and not frost-resistant, and has an unpleasant odor. Positive properties include:

- resistance to chemical compounds (acids, alkalis, solvents);

- does not burn when exposed to air;

- low cost.

IMPORTANT! Many manufacturers produce multi-layer leatherette. If the seller proves that this is polyurethane, but the product emits an unpleasant odor, you can be sure that under the PU layer there is a polyvinyl chloride sheet.

Finishing, fastening

The last stage in the production of leatherette is the processing of the last layer. If the product is made using a simple method, the surface is sanded, embossed or painted. If it is manufactured in a portable manner, the outer covering is laid down in the first stage of production using the texture of the paper layer.

The last stage in the production of leatherette is the processing of the last layer. If the product is made using a simple method, the surface is sanded, embossed or painted. If it is manufactured in a portable manner, the outer covering is laid down in the first stage of production using the texture of the paper layer.

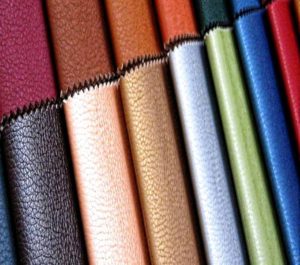

Reference! Using various dyes, they achieve any shades that imitate animal skins. The result is single-color or multi-color canvases.

Conclusion

Thanks to artificial substitutes, humanity has solved the problem of the shortage of natural materials. Complex technological processes and various additives eliminate various shortcomings in leatherette, increase their strength and softness. Things made from them turn out to be practical and versatile when worn.

0

0