The main raw material for making shoes is leather. It is particularly reliable, wear-resistant and durable. Since ancient times, leather shoes have been very popular, and the demand and price for them are constantly growing. Let's consider the characteristics of each material.

The main raw material for making shoes is leather. It is particularly reliable, wear-resistant and durable. Since ancient times, leather shoes have been very popular, and the demand and price for them are constantly growing. Let's consider the characteristics of each material.

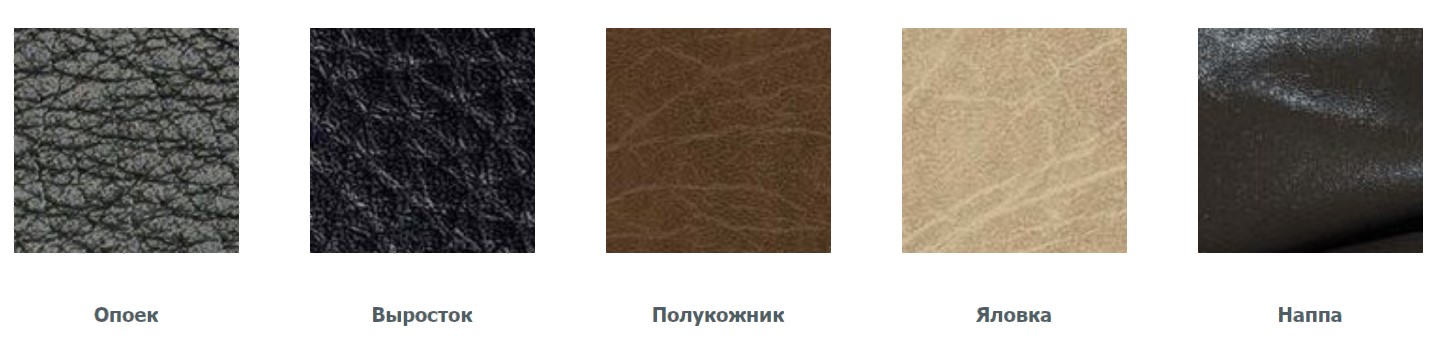

Types of leather for shoe production

Manufacturers distinguish dozens of modifications, differing in elasticity, moisture and breathability, size, durability, and design. Then we list the specifics of individual types used to make shoes.

From cattle

This is one of our favorite and frequently used materials. Leather has a large number of varieties, finishing methods and embossing options. Let's look at the main types in more detail.

Opoek

Represents skin from very young calves up to 3 months. It got its name because the animals are still breastfed. Therefore, their skin is especially delicate, soft and thin. However, it is a mistake to believe that it is less durable.In terms of durability, this species is not inferior to the cover of adult livestock. This can be explained high content in the collagen structure. But if the calf is given only water, the cover will be less tender.

Outgrowth

That's what they call skin grown calfwho grazes and eats hard food on his own. His skin is preparing for the first moult and noticeably coarser than those of the molds.

Half-skin

This skins of heifers and bulls no more than one and a half years old. Their weight in pairs is about 10-13 kg.

Yalovka

Yalovka is cow hide. Moreover the skin of a non-calving animal is denser and more uniform by thickness. The quality is better than beef. The skin of a calving cow has a small saddle cloth and large thin flaps.

Bychina

This skin of bulls that have already been castrated. It has sparse hair. This one of the thickest and heaviest skins, has a rough and porous texture. The heaviest is buffalo leather. It has great strength, but is rarely used in sewing products.

Nappa

Nappa

Thanks to double tanning, the material is soft, and it is very pleasant to touch. Most often, due to its technological processing, it is semi-aniline and has spectacular decorative properties. Depending on the nappa processing methods can be shiny or matte, smooth or rough. Top manufacturers are Türkiye, Spain and Italy.

Small cattle leather

Unlike cattle skins, this the material is softer and more comfortable to work with. Let's look at popular varieties.

Kid

This soft goatskin. The texture has a small ornament. Thanks to its special workmanship and elite appearance, chevro is very expensive.

Kid

Shagreen

This type is prepared from sheep and goat skins. Shagreen has a large pattern. They are mainly used for sewing the tops of boots.

Shagreen

Shervet

This is the type of raw material produced made from sheep skins. The structure of the material is porous, therefore, to increase mechanical strength it is moistened in polymers. Shoe chevrette is made from sheepskins of Russian and steppe breeds of sheep.

Chevrette

Morocco

People started talking about morocco quite recently. It is called almost eternal, since it does not wear out and is resistant to damage and abrasion of the surface.

Morocco shoes

Many people confuse it with eco-leather, but it is completely natural sheep or calf leather. During production, it is placed on a textile base and an impression is made, and then treated with a thin layer of wax.

Morocco

Pigskin

It withthe most budget type. It is used for the production of cheap shoes and insoles, including orthopedic. Due to the peculiarities of the texture, it does not have a very pretentious appearance.

Pigskin

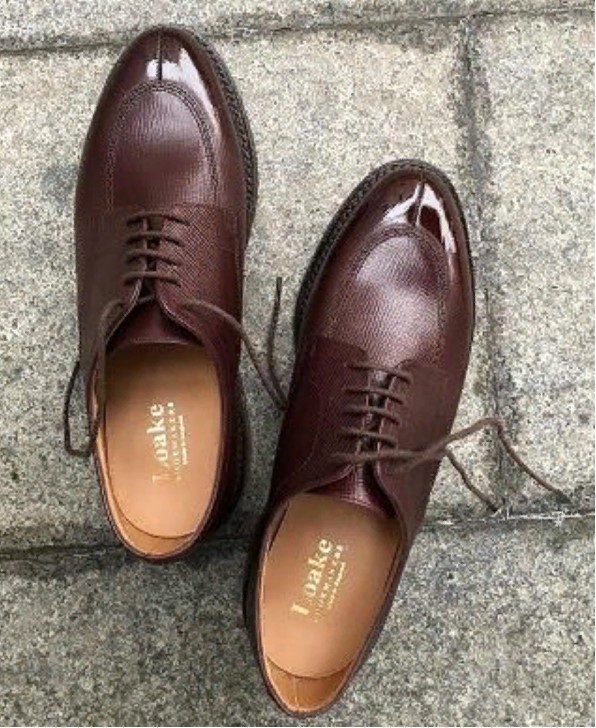

Cordovan

Material is mined from the bottom layer of horse skin. Cordovan known for its durability, strength and wear resistance. It can last much longer than calfskin. However it is more expensive, the procedure for its manufacture is labor-intensive. One of the nuances is that wearing it in hot weather is impractical.

Cordovan leather shoes

In the classic version, cordovan shines; there are options with little or no shine. Over time, the places of folds and the greatest load fade, and the creases take on a wave-like shape.

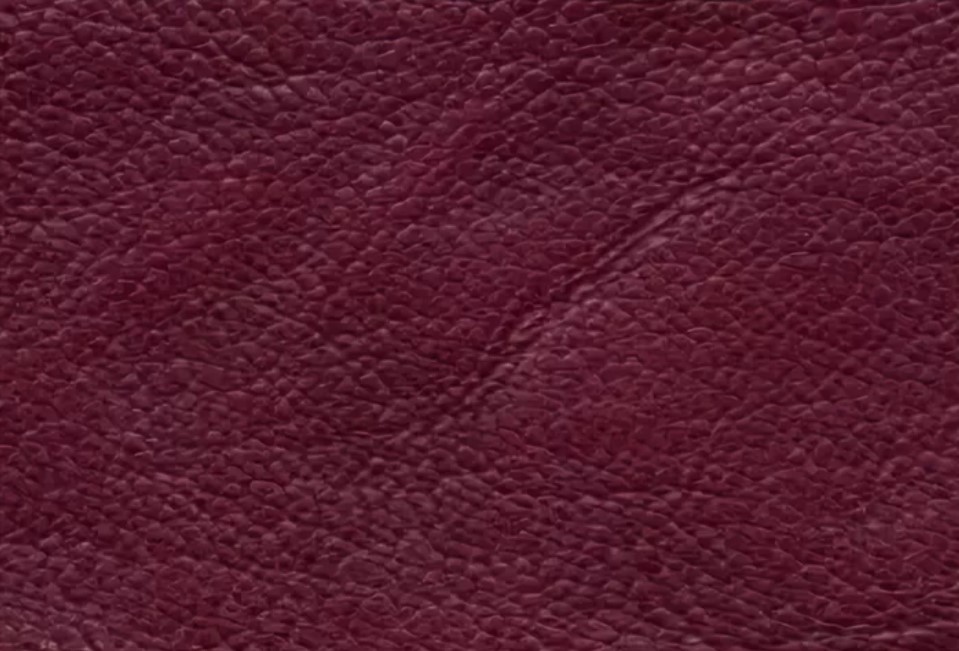

Smooth veal (calf)

This is certainly common and universal material for shoe production. Calfskin has a lot of advantages, and is not too expensive.For more budget models, cow or bull hide is usually used, and calfskin is more breathable, shiny and warm. A universal option for calfskin is box calf. More often she Available in black, terracotta or dark crimson.

Glassage

If desired you can polish it to a glossy finish. Glazing is a labor-intensive process and is expensive. Showrooms often do it as an additional service. Its essence is polishing with shoe polish and water. The material becomes softer and sinks down, and shoe polish fills the wrinkles and roughness, creating a glossy layer.

Glassage

Subspecies crust

This type is not dyed at the tannery, but during sewing at the factory. The material is vulnerable to negative environmental factors such as moisture, dirt, salt and reagents. If your shoes have picturesque stains, then you should not wear them in the rain and snow. Also, you need to be very careful when cleaning and lubricating products with cream.

Fatty calfskin

This type of texture quite smooth, but differs significantly from box calf. Also it's called chromex or mancalf. During the manufacturing process, it is enriched with fats, which makes it even more resistant to water and dirt. It is much more suitable for walking in rainy weather compared to crust.

Pigmented

The leather is completely sanded, then several layers of topcoat paint are applied to the surface. After sanding, a certain pattern is applied to hide minor flaws.. Pigmentation impairs breathability, and an additional polymer coating can reduce it to zero. The appearance of such shoes is less noble, and craftsmen prefer not to use them. One of the advantages is the inexpensive price category.

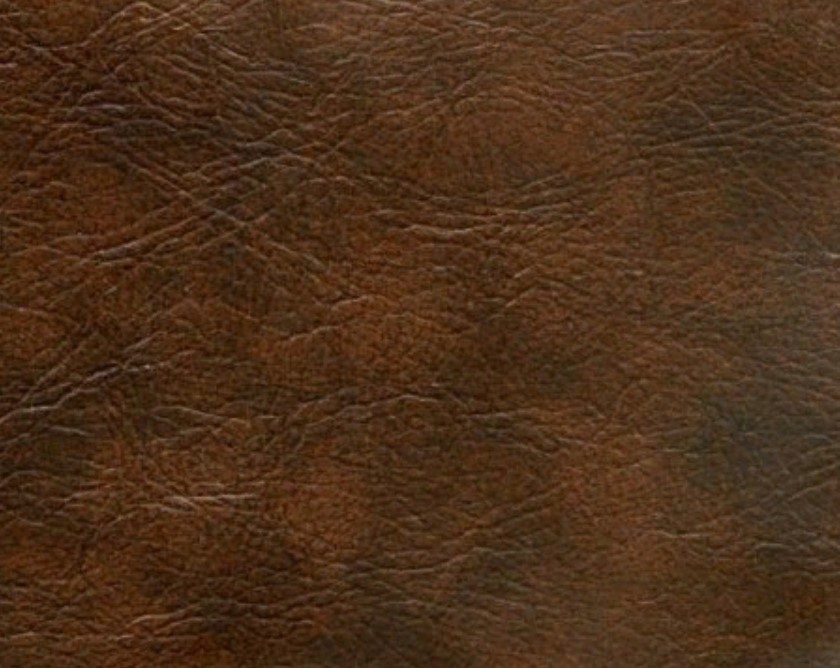

Box calf grain leather

Grainy can be cow and sometimes veal. Using additional presses prints are applied to it. In addition, the material is treated with wax for greater moisture resistance.

Leather type box calf resistant to external factors and ideal for autumn-winter period. The grainy texture goes well with a huge number of materials, both dense textured and smooth thin ones.

Grain leather shoes

Nubuck

It has a soft and velor texture to the touch. The front part is covered with pile. Moreover, it is much smaller compared to suede. The material is durable, perfectly breathable, and with careful handling can last a long time.

Nubuck boots

Oiled nubuck

It is called "nubuck-oil" At the first stage, the leather undergoes exactly the same processing as regular nubuck. The material is then passed through a well-heated cylinder, through which the essence of oils and waxes is applied. Next, the nubuck is dried for 24 hours.

The oiled texture is more durable, easier to clean and repels dirt. Longer service life guaranteed.

Suede

Suede is a natural base, coated with aniline dye, as well as polishing with abrasive substances. Made in two ways. The first method is that during processing the material is passed through a machine; it cuts it into two layers, one of which is used to make suede. The second method is to turn the skin inside out and process its inside.

Suede has an impressive and presentable appearance and is considered a material for casual shoes.. Shoes are often worn with business looks. The material is porous, perfectly permeable to moisture and air. The downside is that suede requires a lot of care.

Aged leather

Thanks to a unique coloring technology, as a result of which the concentrate is absorbed unevenly, it feels like part of the surface has been erased. However this trendy decorative effectetc. Sometimes a more striking result can be achieved by embossing.

Embossed leather

This kind are obtained from skins with obvious flaws, which are hidden using a convex, embossed image. With the help of modern technologies you can create a memorable ornament, as well as an imitation of expensive types of covers of snakes and turtles. This material is inexpensive.

Washed skin

This is completely treated leather or suede. It is specially moistened and then ironed with a hot press. After this, the texture has a slightly shabby appearance. More often in this way they make decorative elements to give the boots originality.

patent leather

The material is obtained by applying a thin layer of synthetic varnish after painting. The thickness of the coating is about 0.006 - 0.7 mm, and increasing it leads to a decrease in flexibility. The material is quite durable, but it hardly breathes.

Lacquered items are indispensable when creating an evening look and always remain at the peak of fashion. The varnish can be embossed and imitate different textures. However, it is poorly susceptible to surface treatment without damage, so when purchasing you should pay attention to the quality of the gloss.

Exotic leather

This type is used for the production of expensive and exclusive shoes. Famous fashion designers use the skin of eel, crocodile, iguana and other reptiles. They are rarely used in the manufacture of classic shoes.In general, the darker the shoes, the more expensive and serious they look.

Crocodile

The most popular leather in this category is crocodile. It is very wear-resistant and flexible, not susceptible to moisture and time. Several different animals may be hidden behind this designation. Alligator and Nile crocodile are always at a premium. But caiman is considered a relatively cheap option, since the texture is less flashy and pleasant. However, products made from caiman are much more expensive than similar models made from calfskin.

Snake skin, eel and other animals

Snake skin has an extravagant appearance. Considered the most effective python skin. It is particularly soft, smooth and shiny. Due to its good dyeability, various colors can be found.

The trending trend in the world of fashion industry is fish skin. On the territory of Russia for these purposes salmon, sturgeon and carp are specially grown. It has a specific texture, is unusual and durable.

Thanks to its sophistication eel skin highly valued all over the world. The material has an interesting striped pattern and is soft. Eel skin is less durable, but is sold at an attractive price.

Kangaroo leather

Compared to other types of skin, this one of the most durable options. The kangaroo cover is several times thinner than the calf cover, so the boots are much lighter. Despite this it is six times stronger than the average material. The exclusivity of the products is due to the fact that Australian legislation strictly controls the export of samples.

Ostrich and stingray

Ostrich leather is less popular and there is little demand for it, as it has a specific appearance. Many fashion designers agree that the surface looks like the enlarged skin of a plucked chicken. Thanks to the natural ingredients it contains, it is more elastic and does not dry out and crack.

Stingray skin also used only for designer models. The material is durable, does not require special care, does not burn or break. Often cowboy boots are made from stingray and ostrich.

To buy suitable leather shoes, you need to have a good understanding of its types and features. Of course, an ordinary person hardly needs to remember all the types, because you can always turn to a more competent seller for help.

0

0