Taking care of the environment is everyone's business. It can be manifested in different ways. For example, create shoes that are easily recyclable or quickly decompose. Emily Burfeind, a German designer, came up with sneakers whose upper part is made from dog hair, and the sole is made from mushroom mycelium. These shoes are not only environmentally friendly, but also incredibly comfortable. Let's get acquainted with an interesting new product.

100% natural

Usually such an inscription can be seen on any food product. And it’s not a fact that it reflects the actual composition. But the Sneature sneakers live up to this statement, which is beyond doubt. The composition of the shoes includes:

- combed dog hair;

- mushroom mycelium;

- liquid natural rubber;

- hemp cellulose substrate.

Now let’s figure out what product is obtained from such raw materials.

@altyn-orda.kz

Sneaker upper

The shoes are produced without laces. Its base is a seamless sock made from dog hair.Combed material is used and spun into high quality yarn. It is known as chiengora, and is distinguished by the fact that it retains heat 42% better than, for example, sheep's wool.

This yarn was historically used by the indigenous people of the West Coast of the United States.

Thanks to the use of three-dimensional knitting technology, it is possible to use a variety of designs, customizing shoes according to individual requests. This possibility is achieved through the software creation of each individual row.

This material can be modified to be softer or stiffer in certain areas, more breathable, or highly elastic in others. The technology allows you to customize the size, shades and patterns of eco-friendly sneakers.

Sole

The resulting top is dipped into liquid natural rubber. The raw material for the latter is the sap of the Hevea brasiliensis tree. This step is necessary to create a water-repellent sole.

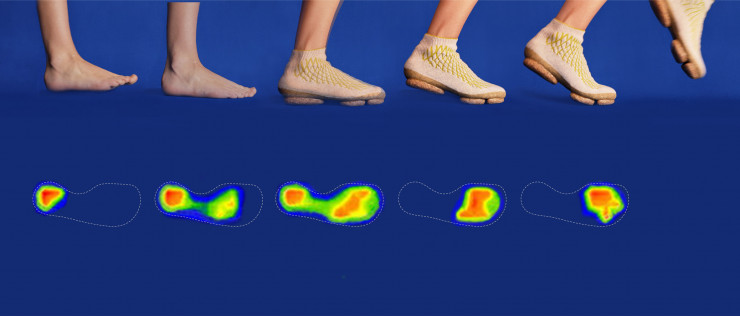

Mushroom mycelium forms a mixture with several natural components: cellulose substrate from hemp and other agricultural waste. It is grown in a specially prepared form to create a sole from the inside and outside. This blank interlocks with perforations on the underside of the sneaker's knitted upper, which helps hold the pieces together and stabilize the shoe.

@tengrinews.kz

Features of production, shelf life and recycling possibilities

Because Snature is made from bio-waste, the manufacturing process requires no energy. It is needed only for subsequent processing.And the amount required is much less than when extracting oil-based raw materials, which is used to produce most models of traditional sneakers.

According to the designer, such shoes can be used for about two years before they wear out too much. After this time, the mycelium composite is optimally crushed for reuse, and the fabric is disassembled into individual fibers and again spun into yarn.

As an alternative, the product can be decomposed in an industrial composter (this will take about a month) so that the nutritious raw materials from which it is made can again enter the ecological natural cycle.

Instead of a conclusion

This is not the first time mushrooms or other natural and unusual materials have been used in the production of shoes or accessories. For example, Adidas presented the first model of sports shoes made from innovative raw materials based on Mylo mushrooms. The material of the sneakers looks and feels like leather. And the German company nat-2 brought to the market not only shoes made from “mushroom” material, but also models of sneakers made from coffee, hay, dairy waste, wood and even natural stone. However, this will be discussed in another article.

1

1