Belt loops are an indispensable part of classic trousers. They should securely fix the belt on the waist or hips. From this article you will learn what belt loops are made of and how not to spoil the entire product with one seemingly unnoticeable detail.

Quantity, width and length

The number of belt loops may vary depending on the size of the model and the location of the belt. If you want to place it at the waist, and the model is a standard size, you will need 5 parts.

The number of belt loops may vary depending on the size of the model and the location of the belt. If you want to place it at the waist, and the model is a standard size, you will need 5 parts.

The belt loop width can be from 1 cm to 3. The length is determined by the width of the belt. To cut out fabric for belt loops, you need to measure the width of the belt, multiply it by 5 (the number of parts) and add 15 cm to the result. This is the full length of the stitch.

The maximum width can be 3 centimeters. After processing and ironing it will decrease.

How are belt loops made?

The entire manufacturing process can be described in 5 stages:

The entire manufacturing process can be described in 5 stages:

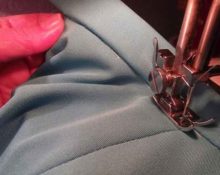

- When the workpiece is cut, using a sewing machine, an even stitch is sewn along the long edge. Please note that the stitching is done from the front of the fabric.

- The remaining raw edge is ironed 1 centimeter inward.

- The piece is turned over and ironed again so that the edge of the overlocker reaches the bend line.

- We sew what we got from the front side. The indentation is 1 millimeter from the ironed edges of the part.

- We cut the already stitched tape into 5 equal parts. They will be sewn to the product.

How are belt loops sewn on?

The belt loops are sewn on before sewing on the belt.

The belt loops are sewn on before sewing on the belt.

Important! Try not to place the belt loops exactly on the sides of the product. Otherwise, they will inevitably stand out when worn, spoiling the silhouette of the figure.

The edge of each part is sewn to the edge of the product (without a belt) and secured with another line one centimeter below.

The upper part of the belt loop is sewn to the back of the belt, secured in the same way.

3

3