The action that eliminates creases and lasses, while giving the correct shape to the trousers, is called wet-heat treatment. WTO gives off heat and moisture.

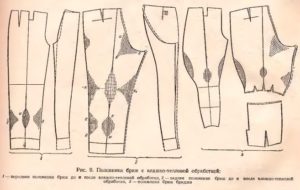

A lot of time is spent on wet heat treatment (WHT) when sewing trousers. Thus, it improves the shape of the product and the fit. Because at the end of the WTO, the pants are ironed and contracted under the buttocks and knees. The length of the product becomes shorter. But in the area after the knees, the process is reversed, the trousers stretch and therefore the length becomes longer. Ironing, or WTO, must be carried out for various parts or seams of a given product during the manufacturing process. Or gluing parts to give shape and volume. The procedure is carried out with a press or iron. Steaming a product is a labor-intensive process that takes up almost twenty percent of the total production time of the product.

A lot of time is spent on wet heat treatment (WHT) when sewing trousers. Thus, it improves the shape of the product and the fit. Because at the end of the WTO, the pants are ironed and contracted under the buttocks and knees. The length of the product becomes shorter. But in the area after the knees, the process is reversed, the trousers stretch and therefore the length becomes longer. Ironing, or WTO, must be carried out for various parts or seams of a given product during the manufacturing process. Or gluing parts to give shape and volume. The procedure is carried out with a press or iron. Steaming a product is a labor-intensive process that takes up almost twenty percent of the total production time of the product.

Why is the WTO done?

After cutting, it is necessary to carry out a wet-heat treatment.

After cutting, it is necessary to carry out a wet-heat treatment.

ATTENTION! To get a good fit on your trousers, be sure to have your product processed!

After processing, you can change the dimensions of the product as intended. Give them shape, volume, according to the human figure. Thus, increasing the level of comfort of the product.

IT IS IMPORTANT TO KNOW! It is performed mainly by WTO, on narrow models, classical style.

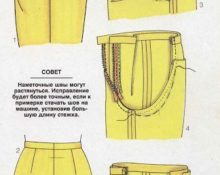

Ironing is the reduction of edges after wet-heat treatment, and as a result, convex shapes are obtained.

Ironing is the reduction of edges after wet-heat treatment, and as a result, convex shapes are obtained.

Pulling - lengthening the edges and obtaining concave shapes in a certain area of the product.

When trousers are made from an unknown material, in order to avoid loss of color and strength, you must first check the effect of the iron on a small piece of fabric.

Ironing on natural fabric must be done through the fabric to avoid lasses.

Having finished processing, at the end, the trousers should be hung up and left to dry. Approximately fifteen to twenty-five minutes.

Features of the WTO of trousers

In order to end up with properly processed trousers, the main rule is to properly organize the wet-heat treatment of the product. To do this, you need to carry out a chain of technologies: choose the right equipment, it must be equipped with steam, compressed air, choose the right processing mode. WTO uses processes that are equipped with pads to iron small items.

In order to end up with properly processed trousers, the main rule is to properly organize the wet-heat treatment of the product. To do this, you need to carry out a chain of technologies: choose the right equipment, it must be equipped with steam, compressed air, choose the right processing mode. WTO uses processes that are equipped with pads to iron small items.

WTO for different types of fabrics

In the nineteenth century, classic-style men's trousers appeared. Designers only change the belt, pockets, fasteners, and other little things, making them according to fashion. High-quality trousers are the basis of a man's wardrobe. The fabric needs to be thick and of good quality. Fabrics on a natural basis, such as wool, linen, cotton, and others, when subjected to damp heat treatment, do not lose their fiber structure.Pants made from fabrics that contain synthetics, after processing, may lose their fiber structure. To achieve the correct fit, you can only use the cutting method. Skinny pants require a WTO more than wide ones. But a cell or strip may lose its pattern. To iron the arrows, you need to iron them in front from the waist to the bottom, and in the back from the hips to the bottom. The procedure does not need to be done on short pants and on fabrics such as viscose, cotton, silk.

You can also use the solution to iron and stretch fabric:

- For half a liter of water, one tablespoon of PVA glue;

- For half a liter of water, three tablespoons of vinegar.

IMPORTANT! Check to see if the fabric is fading, and then iron with the solution.

0

0