It's noticeably colder outside, it's time to warm up. In this article, we’ll look at how to sew a women’s down jacket with your own hands. The task is quite difficult, but quite doable. Let's add a few unique elements that will make our product exclusive.

It's noticeably colder outside, it's time to warm up. In this article, we’ll look at how to sew a women’s down jacket with your own hands. The task is quite difficult, but quite doable. Let's add a few unique elements that will make our product exclusive.

How to sew a winter down jacket with your own hands

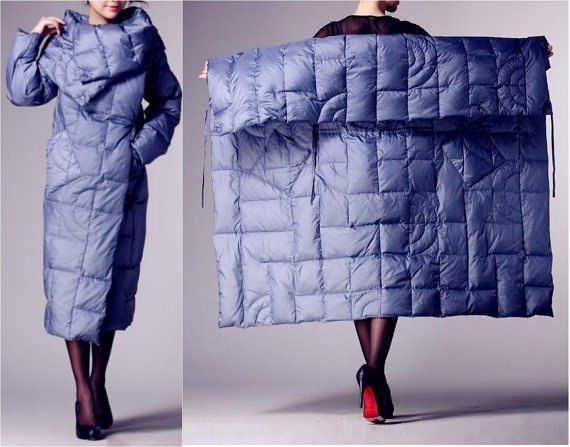

Let's take as a basis the oversized style, which continues to gain popularity among fashionistas. Today we will try to sew quilted down jacket with a collar-hood.

Materials and tools

The outer material for sewing a down jacket can be polyamide, polyester or nylon. All of them consist of synthetic fibers, have increased wear resistance, do not wrinkle, do not allow moisture to pass through and protect from wind. Polyamide is also good because it removes fumes and dries quickly. A distinctive feature of nylon is its lightness and increased water and steam resistance properties.

ATTENTION! If you plan to wear a jacket in conditions of high humidity, it is better to choose a material with water-repellent impregnation.

Classic down jackets use waterfowl down as filler., as it has natural water-repellent properties. Such fluff will never stick together or mat, since human sweat and skin fumes do not settle on it. But it will be very difficult for a novice dressmaker to sew a jacket with such filling, and it is not cheap, so we will focus on the simplest option - padding polyester.

For sewing the lining we choose polyester - synthetic knitted fabric that looks like wool. It is affordable, easy to care for, antistatic and practically wrinkle-free.

From the accessories we will need magnetic buttons, which we will use as a clasp.

Standard set of tools:

- sewing machine;

- overlock;

- scissors;

- tape measure;

- graph paper;

- pencil;

- chalk;

- needles, pins.

Down jacket pattern

The pattern will be as simple as possible, so we take a minimum of measurements:

- down jacket length;

- back width;

- armhole height;

- the length of the sleeve

IMPORTANT! When taking measurements, it is necessary to immediately include an increase in the freedom of fit. For outerwear it is about 8 cm.

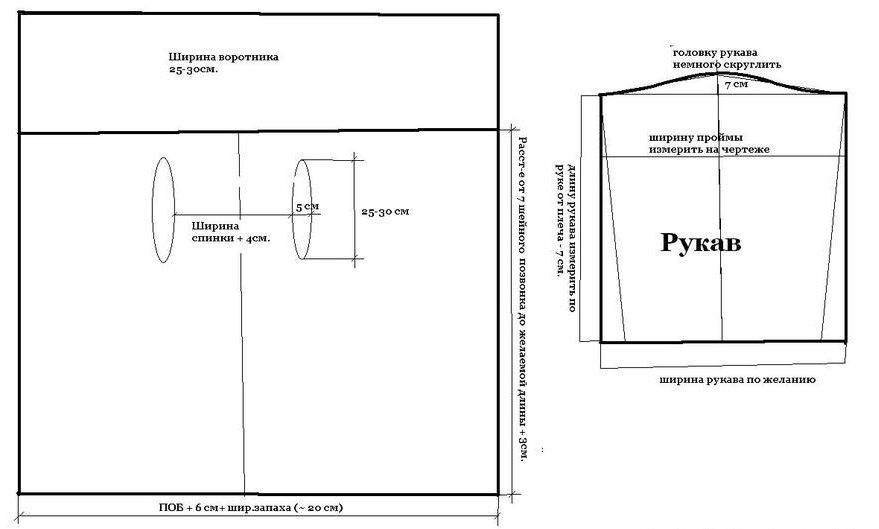

We build a pattern drawing

- We put down the width of the collar 25–30 cm + the desired length of the down jacket. At the level of the collar we draw a horizontal line. From the top left point to the right we set aside a width that is equal to the width of the back * 2 + the width of the wrap (about 20 cm) + 6 cm.

- Mark the central axis. We will place armholes at an equal distance from it, 5 cm wide and 25–30 cm high.

- To construct the sleeve pattern, we build a rectangle. It can be made straight or tapered.We measure the width of the armhole according to the drawing of the main part. We make the sleeve head rounded.

Cutting materials

- We cut out the main part from the outer material and padding polyester.

- Additionally, from the same fabric we cut two parts for the lining and one for the collar.

- We cut out the sleeves directly from the outer fabric, lining and padding polyester.

IMPORTANT! It is necessary to leave 2.5 cm for allowances on each side and 5 cm for processing the bottom.

Stages of sewing a down jacket

- Sections of parts from outer and lining fabrics we process it on an overlocker or on a sewing machine using a zigzag stitch.

- Fold the main rectangle with the additional detail of the gate face to face, baste, and then grind down them on a sewing machine. Similarly, we sew two edgings on the sides.

- Let's move on to cutting out the lining for the main part. We cut a rectangle of such a size as to fill the space on the wrong side between the ribs and the collar.

- Carefully put padding polyester inside, matching the corners.

- On the front side, using a soap remnant, we outline the stitch lines along which we will quilt the fabric. To prevent the stitches from moving apart, we fix them with safety pins and lay basting ties using a thin needle. On the collar and collars we stitch (quilt) 3 layers of material, outer, padding polyester, outer. In the place where the lining will be, we quilt 2 layers - outer material + padding polyester.

ATTENTION! To prevent the padding polyester from slipping on the fabric, you should initially sew it around the perimeter. Since the fabric turns out to be quite dense, it is more advisable to use a walking or Teflon foot on a sewing machine.

- The same way quilt the sleeves. When applying padding polyester to the sleeves, you need to retreat 5 cm from the bottom edge (cuff).The insulation is not sewn to the bottom seam allowance, because it is intended to be folded inward and connected to the lining.

- We machine sew the shoulder seams. To prevent the down jacket from slipping off your shoulders in the future, we make two parallel seams at a distance of 2 cm from each other and insert a cord into them, which will be tightened around the neck. You can take the lace ready-made, but it is better to sew it from the main fabric.

- Sew the side seams of the sleeve from the outer fabric (which is already quilted with padding polyester) from the wrong side, then we sew down the side seam of the sleeve lining. Place the lining and main sleeve face to face and sew the bottom edges. Turn it inside out and insert the lining inside. Then he turns the cuff inward, bastes, irons and places a decorative seam along the front side at a distance of 2-3 mm from the edge.

- We sew the sleeves into the “body” of the jacket. To do this, we find the centers of the edges and connect them to the shoulder seams. We stick them into the armholes with safety pins and baste them so that a small fit is formed. We make a machine seam, the upper thread should pass along the sleeve part.

- Sew in the main part of the lining. To do this, we place the main part with the padding polyester facing up and connect it to the lining on three sides, except for the hem.

- We turn the down jacket inside out through the bottom edge and pin it, baste it, and then We machine sew the lining to the main material. We make a line about 10 cm short of the middle. On the other side we do the same operations. Turn the jacket inside out. Fold and iron the middle. Using safety pins, we fix the unstitched area and stitch it manually with hidden ties. The lining is sewn.

- Sew on magnetic buttons at an even distance from each other.

- In addition to the buttons, you can add a belt. We cut it directly onto the fabric.The width of the belt part, taking into account the allowances, is 10 cm, the length is 150 cm. For additional rigidity, we glue the back side with non-woven fabric or double-lined fabric. We sew short sections from the inside. Turn it inside out and iron it. We make a hem along the long cut by 0.5 - 0.7 cm and iron it. We baste and lay a decorative stitch along the front side at a distance of 1–2 mm from the edge.

The down jacket is ready!

2

2