A woman should always look beautiful, no matter where she is: in the office, theater or at home. Her attractiveness is emphasized not only by well-chosen makeup, but also by her clothing style.

A woman should always look beautiful, no matter where she is: in the office, theater or at home. Her attractiveness is emphasized not only by well-chosen makeup, but also by her clothing style.

A chic dress for a corporate event, a formal office suit or comfortable, discreet-looking loungewear must be made impeccably, with the correct cut of the fabric and neatly stitched details. The slightest violation in the position of the stitching or an incorrectly processed design element can ruin even the most sophisticated outfit.

Incorrectly placed slots during pattern calculation or sloppy stitching can ruin all the designer’s work. Therefore, before starting to design a circuit, you should familiarize yourself with the design rules.

Definition and location of the vents on the skirt

In modeling, there are many similar concepts that nevertheless have different purposes and, consequently, different processing methods.

Attention! The slot, unlike a regular cut, is an open fold that overlaps the second half of the product.

The slot is used more often in classic styles of cutting suits, jackets, raincoats, coats or short coats, etc. Less commonly used in lighter models (evening dresses, denim suits, etc.). When processing vents, special attention must be paid to the style of clothing, the quality and thickness of the fabric, as well as the type of tailoring - with or without lining.

Having learned how to stitch a part without a base, all other types of processing will not be difficult. Let's take a step-by-step look at how to sew a vent on a skirt.

Having learned how to stitch a part without a base, all other types of processing will not be difficult. Let's take a step-by-step look at how to sew a vent on a skirt.

Groove location

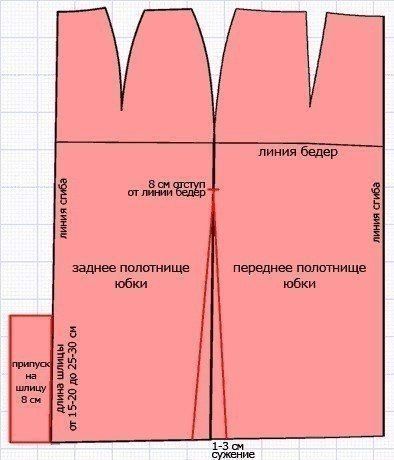

When designing a pattern for an office-cut skirt, the vent is placed mainly along the center line of the back seam, less often along the sides or the raised front stitch.

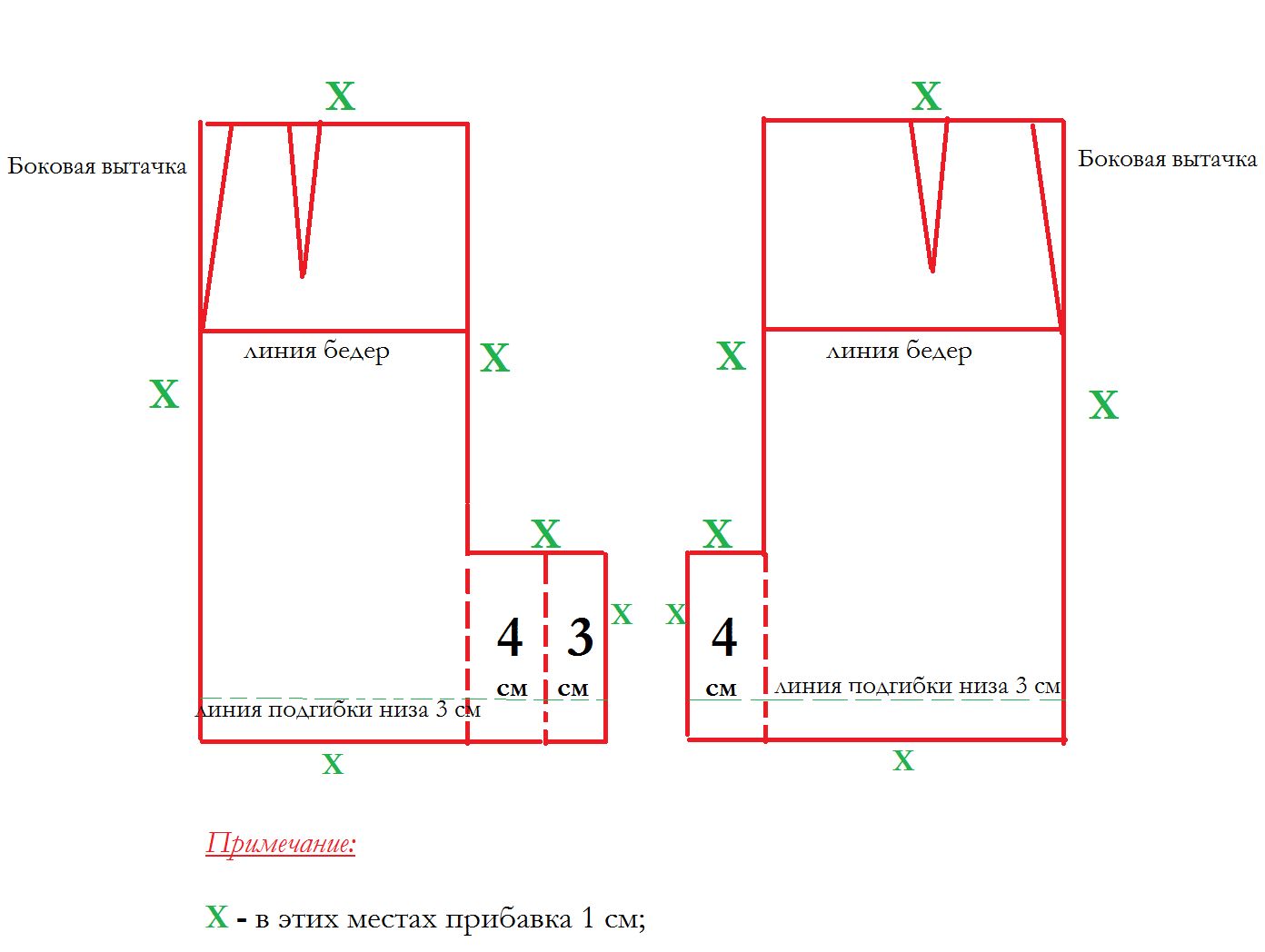

Experienced seamstresses use prepared samples of classic models for cutting, adding a fold directly when transferring the sketch to the canvas.

Experienced seamstresses use prepared samples of classic models for cutting, adding a fold directly when transferring the sketch to the canvas.

For beginners, it is advisable to mark it out on paper first.

For beginners, it is advisable to mark it out on paper first.

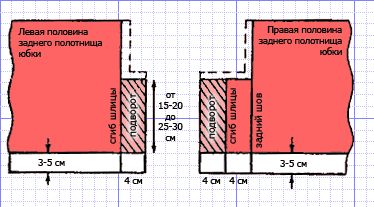

It is advisable to calculate the location of the slots based on the size of the product. To do this, take its full length minus 15-25 cm from the bottom edge. The length of the groove itself depends on the location of the bottom strip of the completed item: at knee level, above or below it.

It is advisable to calculate the location of the slots based on the size of the product. To do this, take its full length minus 15-25 cm from the bottom edge. The length of the groove itself depends on the location of the bottom strip of the completed item: at knee level, above or below it.

Important! When cutting blanks, depending on the thickness of the fabric, it is necessary to make an appropriate allowance for making the groove.

Spline sizes

The size of the skirt's vents varies depending on its model. In this case, it is necessary to take into account the upper point of the beginning of the open fold, since if the position is too high, when using ready-made midi skirts, areas of the body that the user would like to hide will be revealed.

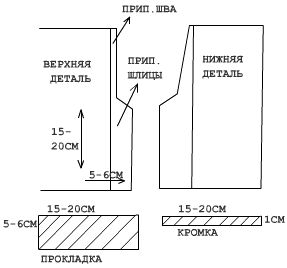

And if it is too short, the width of the step becomes limited and uncomfortable.Nevertheless, there are standard indicators: the length corresponds to 1/3 of the length of the central stitching from the waist to the bottom; the width of the right part is 5-7 cm, the left part is 8-10 cm, depending on the thickness of the panel.

And if it is too short, the width of the step becomes limited and uncomfortable.Nevertheless, there are standard indicators: the length corresponds to 1/3 of the length of the central stitching from the waist to the bottom; the width of the right part is 5-7 cm, the left part is 8-10 cm, depending on the thickness of the panel.

Spline processing technology

Before you start working directly on the spline, first prepare the necessary tools.

You will need:

- sewing machine;

- completed form of the product;

- needles, pins, threads, scissors;

- sewing chalk;

- ruler;

- adhesive tape.

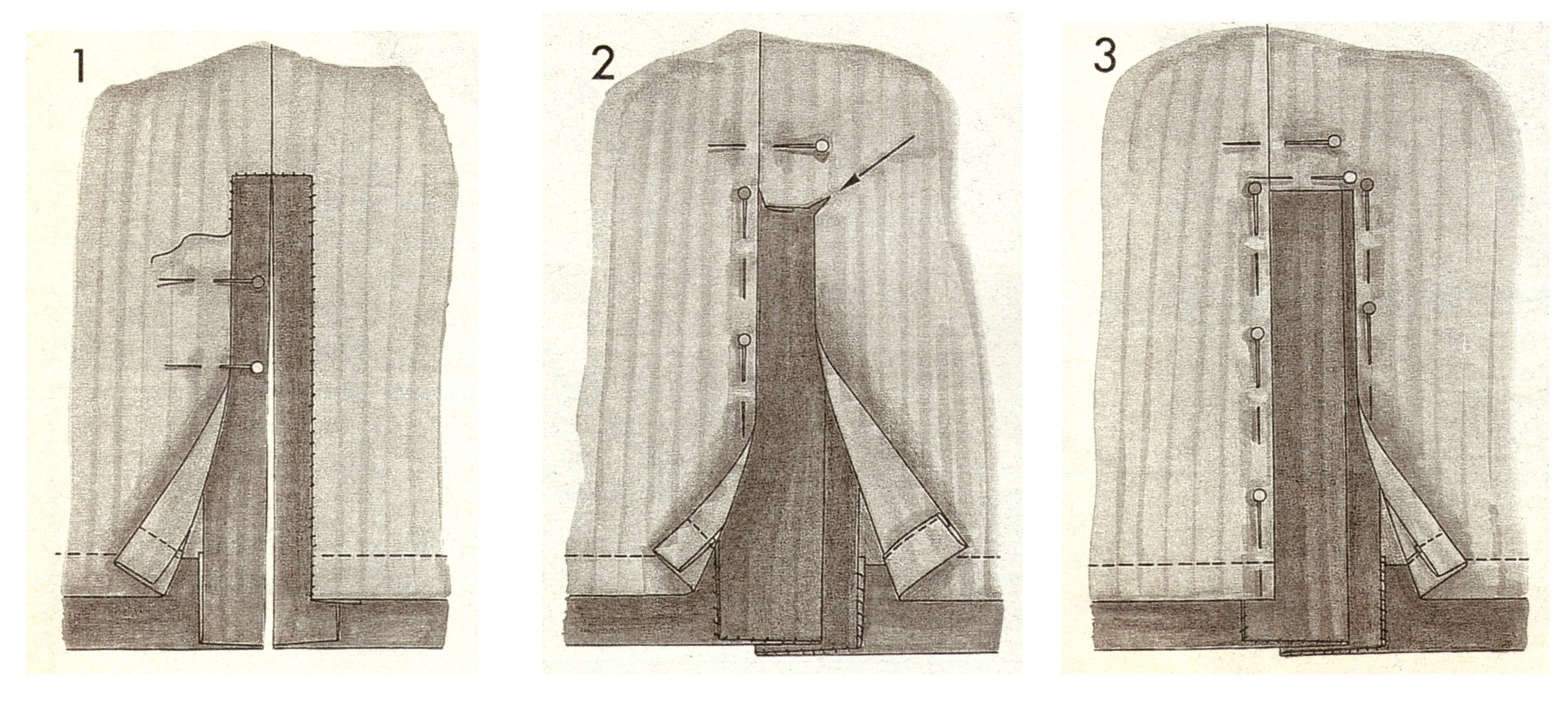

First of all, the position of the slot for cutting is marked. To do this, on a manufactured classic format, an allowance of 50 mm for the hem is measured from the bottom line of the item and ironed along the entire bottom.

First of all, the position of the slot for cutting is marked. To do this, on a manufactured classic format, an allowance of 50 mm for the hem is measured from the bottom line of the item and ironed along the entire bottom.

From the ironed strip on the underside of the right shelf, the length of the recess itself is measured and the upper point of its beginning is marked. The left side is also outlined.

From the ironed strip on the underside of the right shelf, the length of the recess itself is measured and the upper point of its beginning is marked. The left side is also outlined.

Attention! It is necessary to check the accuracy of the location of both points on the pattern - they must be in a mirror image.

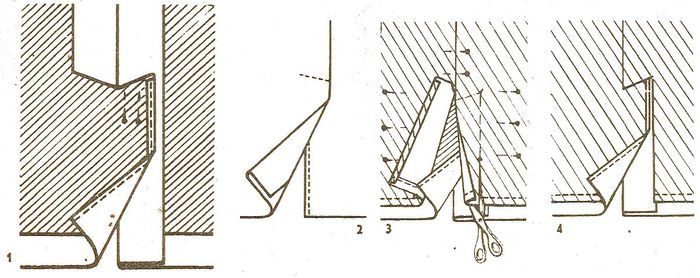

On the right rear panel, a folding width of 50 mm is measured from above and below (for thin woolen fabric, this figure increases for thicker ones) and is carried out strictly at a vertical level. An indicator of 8 cm is also measured on the left side. It is carefully cut vertically, then a diagonal cut is made, not reaching the middle seam of 2 mm.

On the right rear panel, a folding width of 50 mm is measured from above and below (for thin woolen fabric, this figure increases for thicker ones) and is carried out strictly at a vertical level. An indicator of 8 cm is also measured on the left side. It is carefully cut vertically, then a diagonal cut is made, not reaching the middle seam of 2 mm.

Next, the material is folded along the line, secured with pins and ironed. The cooked tenderloin is sewn together. The rear center stitch is laid strictly to the top of the slot.

Next, the material is folded along the line, secured with pins and ironed. The cooked tenderloin is sewn together. The rear center stitch is laid strictly to the top of the slot.

Two strips are cut out of adhesive material (non-woven fabric or the like): the first is 4.8 cm wide, the second is 7.8 cm. The first sticker is glued to the right rear shelf from the inside out, and the 2nd - to the left.

Two strips are cut out of adhesive material (non-woven fabric or the like): the first is 4.8 cm wide, the second is 7.8 cm. The first sticker is glued to the right rear shelf from the inside out, and the 2nd - to the left.

Important! It is necessary to ensure the accuracy of the stickers: they should lie strictly along the center line of the fold and not reach the edge of the cutout by 1-2 mm.

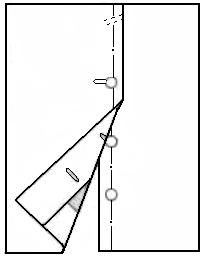

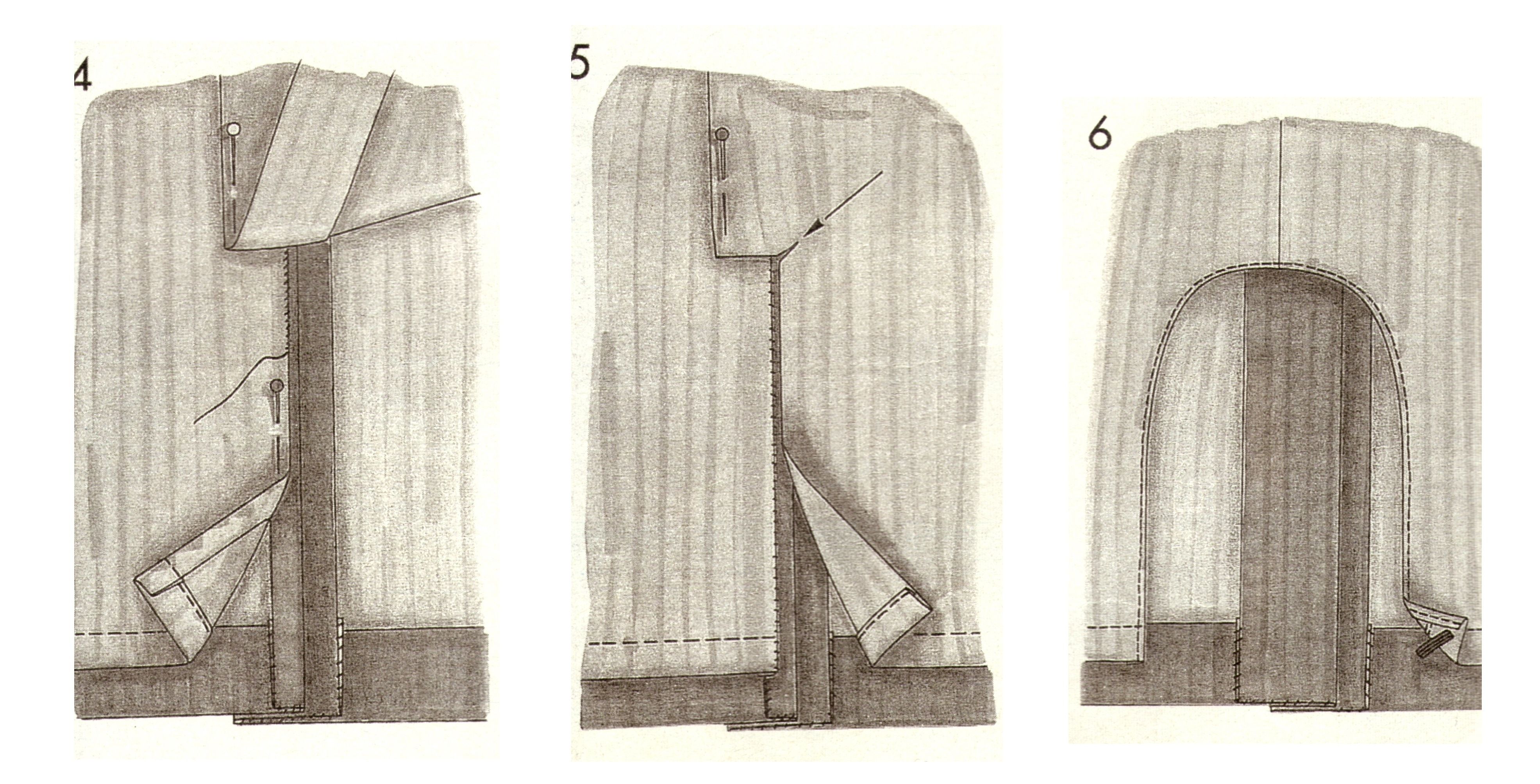

To strengthen the gluing sections, iron the slots with an iron. Overcast fabric sections by hand or with an overlocker, sweep both halves of the product and iron seam allowances. The element located on top must be bent in the opposite direction. From the top spline point down at an angle of 45 degrees, draw a line for the fastening line, copying it onto the front line using a basting line.

To strengthen the gluing sections, iron the slots with an iron. Overcast fabric sections by hand or with an overlocker, sweep both halves of the product and iron seam allowances. The element located on top must be bent in the opposite direction. From the top spline point down at an angle of 45 degrees, draw a line for the fastening line, copying it onto the front line using a basting line.

To avoid shifting of parts during stitching, pin all layers together, lay a securing stitch and pull out the basting thread.

Folding the bottom of clothes

The final operation is hemming the midi skirt. To do this, fold the bottom to the added allowance and iron it all over the circle. Trim the corner of the protruding area by 45 degrees. and fold over the bottom seam allowance.

Attention! When filing the product, you must ensure that the left half is 1.5 - 2 mm lower than the right or is on the same level. But in no case higher!

Hem by hand with a blind seam or stitch on a sewing machine.

Hem by hand with a blind seam or stitch on a sewing machine.

As you can see, Finishing the slots is not difficult. Nevertheless, it requires perseverance, patience and precision from the seamstress.

As you can see, Finishing the slots is not difficult. Nevertheless, it requires perseverance, patience and precision from the seamstress.

Only in this case the result will be positive. The slot made in the middle seam of the back panel of the skirt remains practically invisible. But when moving, it will give additional width, which will make the step more comfortable and confident.

Only in this case the result will be positive. The slot made in the middle seam of the back panel of the skirt remains practically invisible. But when moving, it will give additional width, which will make the step more comfortable and confident.

1

1