Roller shutters are used everywhere in homes, offices, garages, warehouses and the like.

Roller shutters are used everywhere in homes, offices, garages, warehouses and the like.

They are made from a variety of materials, have different control systems, but agree on one thing - they are easy to use and combine several functions.

Roller shutters are designed to protect premises. They are used in a variety of cases: as protection on windows, as doors on garages and commercial containers, to cover store windows during non-working hours, even to divide an office into sections.

They can have different appearances, making them fit very well into any interior. It does not have to be a standard rectangular design, they can be custom made to fit irregularly shaped holes. A special box is provided for rolled up roller shutters so that they do not spoil the appearance of the room. You can even hide this box inside the wall.

Important! Roller shutters are divided into electric and mechanical, depending on the roll-up system.

They are mostly made of metal, but there are also plastic versions.Roller shutters perform several functions at once. They decorate the room, protect against the entry of strangers, can cover from excess light and, with the advent of new technologies, help with thermal insulation.

They are mostly made of metal, but there are also plastic versions.Roller shutters perform several functions at once. They decorate the room, protect against the entry of strangers, can cover from excess light and, with the advent of new technologies, help with thermal insulation.

Roller shutters consist of four parts: the canvas itself, the control mechanism, guides and control elements. Installation is possible at any stage of construction. Unlike bars on windows, roller shutters prevent vandals from breaking glass.

Very often, vandals paint graffiti on roller shutters. In this case, it is better to remove the paint immediately, but if for some reason the disgrace was noticed after a few days, then there is also a way out.

Very often, vandals paint graffiti on roller shutters. In this case, it is better to remove the paint immediately, but if for some reason the disgrace was noticed after a few days, then there is also a way out.

When removing paint, you need to take care of your own safety - wear gloves and a protective mask. After this, you need to apply the solvent liquid onto the unwanted pattern with smooth movements, trying not to touch the roller shutter fabric itself. The liquid should sit there for about 5-10 minutes.

After this, you can remove the paint with a soft cloth. It is better to remove paint from technological crevices after completing the main cleaning with a thin brush dipped in a solvent.

If the drawing is completely fresh, then a quick wipe with white spirit or any other construction solvent will do. If the paint is already old, then you need to use a special solvent “Removing Old Paint”. It does not corrode the paint on roller shutters, but it removes drawings with a spray can very well.

To dismantle you need to prepare. If they are electric, then first of all you need to disconnect them from the network.In the case of mechanical roller shutters, the main difficulties will be in removing the frame, because the frame together with the canvas is very heavy.

To dismantle you need to prepare. If they are electric, then first of all you need to disconnect them from the network.In the case of mechanical roller shutters, the main difficulties will be in removing the frame, because the frame together with the canvas is very heavy.

Dismantling begins by winding the canvas into a box, then disconnecting the limit switches from the shaft. If the control is manual, then first remove the control fastenings using a screwdriver, then use a key to remove the box fastenings. At the very end, the guides are dismantled. If the roller shutters are electric, then you need to disconnect the roller shutters from the main control, wind up the cable, and then calmly dismantle the box and guides in the manner already indicated.

Hammer, screwdrivers, wrenches of various diameters, protective gloves. More detailed information can be found in the instructions for the roller shutters.

There are a number of common breakdowns of roller shutters that you can fix yourself.

If foreign objects or dirt accumulate in the guides, the slats may become deformed or fall out of their grooves. In this case, a complete replacement of the canvas may be necessary, but in most cases it is enough to go through the canvas and replace the deformed lamellas.

If foreign objects or dirt accumulate in the guides, the slats may become deformed or fall out of their grooves. In this case, a complete replacement of the canvas may be necessary, but in most cases it is enough to go through the canvas and replace the deformed lamellas.

If this breakdown is not corrected immediately, it leads to deformation of the guides, blockers, and lock. In this case, only replacing the damaged part will help.

When heavy objects fall from above, deformation of the box itself usually occurs. The canvas does not move out at all or does not work correctly. Depending on the extent of the damage, it is necessary to either replace the box or straighten it. Deformation of the guides is also possible, the repair is the same.

Sometimes the side plugs on the canvas fall out. In this case, the blade immediately jams in the guides.It is necessary not only to replace the plugs, but also to completely reassemble the blade; there is no other way to pull it out of the guides.

Electric roller shutters may have problems with the power supply. This can be noticed because the mechanism stops responding to commands or executes them incorrectly. In this case, it is necessary to replace the fuses or wire.

To repair roller shutters, depending on the breakdown, you may need screwdrivers, a hammer, a sledgehammer, a set of sized bolts and nuts, and additional spare parts.

Typically, electric roller shutters have a backup manual mechanism for such cases. If it is not provided, you need to get to the box and separate the limit switches. Then the only problem will be the weight of the canvas itself. Usually in the electric version it is quite heavy, but the inertial mechanism will help you lift it.

Important! During manual opening of the roller shutters, the mechanism must be disconnected from the power supply.

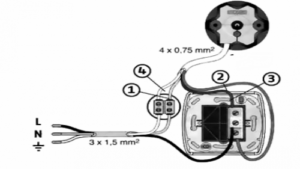

Before installing the roller shutters, it is necessary to accurately select the location and lay holes for the power cables. After this, you need to connect the power unit and the wall switch, adjust the limit switches that directly move the shaft, and check the operation of the system.

There are usually places in the roller shutter box to attach excess wires, so there is no need to try to save it. To lay power cables, a hole with a diameter of about 12 mm is usually drilled, this is quite enough. Before installing roller shutters, you need to check the instructions; they usually indicate the types of cables, all color codes and connection diagrams.

There are usually places in the roller shutter box to attach excess wires, so there is no need to try to save it. To lay power cables, a hole with a diameter of about 12 mm is usually drilled, this is quite enough. Before installing roller shutters, you need to check the instructions; they usually indicate the types of cables, all color codes and connection diagrams.

Before starting work, you need to make sure that when laying technical holes, no other cables in the wall will be affected. All connections must be terminal only, with additional protection with brackets. The entire system must be connected to the electrical network after complete assembly.

When attempting to open electric roller shutters without a key, you must ensure that they are unplugged. Mechanical ones are usually equipped with a spring-inertia mechanism. Therefore, when trying to open it without a key, you need to hold the blade by the special stoppers and under no circumstances rest your palm on the blade. Deadbolt locks can be opened without a key only from the inside, by unscrewing the fasteners. Then the lock must be carefully loosened in the groove until it allows both bolts to be pulled out.

To open electric roller shutters without a key, you need to dismantle the box, disconnect the limit switches and pull the ends of the springs out of the holes on the shaft.

The mounting of roller shutters depends on their type. The box can be mounted outside or inside the opening.

The mounting of roller shutters depends on their type. The box can be mounted outside or inside the opening.

If the box is installed on top, then it is better to use dowels, expansion anchors and other fasteners of this type. For internal installation, expansion anchors must be used. If there are metal structures, it is necessary to use self-tapping screws; wooden structures require through studs. Additional elements are always attached with self-tapping screws.

To fasten roller shutters and their elements you will need a screwdriver, hammer drill, drill, wire cutters, hammer, marker, tape measure, screwdrivers, rivet gun, indicator screwdriver, ladder and sealant.

First of all, the spring-inertial mechanism requires adjustment. Although the instructions recommend calculating the strength of this mechanism using a special table, it is better to do this by eye. It is necessary to screw the spring onto the shaft several times, attach the canvas in place and, holding it with your hand while lifting, make sure that its lower stops rest against the edge of the box. After receiving the result, adjust the number of skeins accordingly - wind up or loosen.

In mechanical roller shutters without a spring-inertial mechanism, adjustment is simple. It consists in the number of revolutions of the blade around the shaft. Adjustment is carried out by opening and closing the roller blind until the desired length is reached. If the canvas does not reach the edge of the opening, lamellas are added to it; if it overlaps, the lamellas are removed.

Electric roller shutters are adjusted by shortening or increasing the duration of shaft rotation. This indicator is adjusted by the location of the limit switches. The position of the switches is adjusted using a regular screwdriver, which is used to tighten the screws.

According to their purpose, roller shutters are divided into garage doors, which use more durable wide profiles, roller shutters for doors and windows, and protective grilles with perforations. Garage doors are usually used in garages, storage areas, retail outlets and the like. Roller shutters for doors and windows can also be used to protect a glass roof from the elements. Protective grilles with perforation primarily serve an aesthetic function; they are used not only outdoors, but also indoors.

According to their purpose, roller shutters are divided into garage doors, which use more durable wide profiles, roller shutters for doors and windows, and protective grilles with perforations. Garage doors are usually used in garages, storage areas, retail outlets and the like. Roller shutters for doors and windows can also be used to protect a glass roof from the elements. Protective grilles with perforation primarily serve an aesthetic function; they are used not only outdoors, but also indoors.

When choosing roller shutters, you need to decide on their purpose, take measurements of the opening and choose the type of installation. The easiest way is to install the roller shutter box outside the opening, but this makes it an easy target for vandals. Therefore, they usually choose to install the box inside the slope. The overhead installation is suitable for residential buildings and private garages that are already in use. Where security and intrusion protection are paramount, it is better to choose the built-in option.

Slats for roller shutter curtains can be made from different profiles. For private properties, light aluminum profiles are usually purchased. Retail outlets and other similar premises require reinforced anti-vandal structures.

The choice of control depends on the weight of the canvas itself. An inertial cord is suitable for up to 10 kg, gear and cardan mechanisms are suitable for up to 30 kg, then it is worth purchasing a spring-inertial drive.

With a mechanical drive, a deadbolt lock is usually chosen, but in electric versions, special electric key locks and top locks are usually used. The second option is more reliable.

Important! It must be remembered that cutting roller shutters to width yourself will lead to loss of warranty and possible breakdown of the spring-inertia mechanism.

The roller shutter blade, shaft and protective cover need to be shortened. The first step is to disconnect the blade from the shaft and pull out the side plugs. After this, the canvas is divided into separate lamellas and, using a grinder, shortened to the required length. Then the canvas is put back together and the side plugs are installed. The box is disassembled, the shaft is pulled out, which is cut to the same length using a grinder.You need to unscrew one side cover from the protective box, then shorten the box in the same way, drill new holes for fastening the side cover and screw it back. Put the whole system together.

The roller shutter blade, shaft and protective cover need to be shortened. The first step is to disconnect the blade from the shaft and pull out the side plugs. After this, the canvas is divided into separate lamellas and, using a grinder, shortened to the required length. Then the canvas is put back together and the side plugs are installed. The box is disassembled, the shaft is pulled out, which is cut to the same length using a grinder.You need to unscrew one side cover from the protective box, then shorten the box in the same way, drill new holes for fastening the side cover and screw it back. Put the whole system together.

Roller shutters are shortened if you made a mistake with the width of the opening when ordering. It is also possible to move it to a new location where the opening width is smaller than the previous one.

To shorten the roller shutter you will need a grinder, screwdrivers, a set of wrenches, a tape measure, a marker, and protective devices.

Roller shutters are very convenient for people who care about their own safety, want to save on electricity and decorate the interior. There are many different types of roller shutters to suit every taste. In addition, this type of protective structures can be installed, configured and adjusted independently.