Natural or artificial leather is a complex material, but things made from it turn out luxurious. Experienced craftswomen say that every seamstress can learn to work with it. The main thing is to remember the features of this material, choose the right tools and not be afraid. Everything will definitely work out! And we will talk about the intricacies of such work in the article.

How to sew leather on a sewing machine

First of all, you need to determine what material is in front of you: natural or artificial. All further work depends on this.

Faux leather

The main problem with such fabric is that it often sticks to the foot and can tear at the puncture sites left by the needle.

Therefore, the working rules are as follows:

- leatherette cannot be chipped with pins;

- It’s better to buy a special foot or use papyrus paper;

- make long stitches;

- The stitch can be done in a zigzag or straight line, but always at a slow speed.

The advice seems simple. But they really work - the risk of spoiling the material when sewing on a machine is minimized.

Genuine Leather

The operating principle here is different from sewing artificial material. However, there are nuances:

- It is better to use a Teflon or conveyor foot. If the first option simply protects the fabric from damage and helps to sew smoothly, then the conveyor foot is needed to protect it from shifting during sewing.

- Papyrus paper also works with genuine leather. If desired, you can add silk paper.

- To protect natural leather, you can place fine, thin sandpaper under the foot (the working surface should be at the bottom). Before sewing the main product, test the “invention” on an unnecessary scrap.

- It is recommended to set the stitch length to 4-5 mm. If the stitches are short, the fabric may tear.

- You also cannot use pins or fastenings here.

Which machine is suitable for sewing leather goods?

Speaking on a large scale, special machines are needed to sew leather items. They are powerful and can sew through even the thickest fabric without damage.

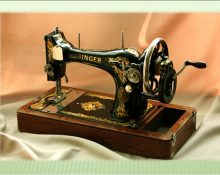

But this does not mean that a home machine is not suitable for working with leather. You just need to choose it correctly. For example, a manual Podolsk machine or some Singer models are suitable.

Important! If we talk about modern electrical options, then there is only one piece of advice: read the instructions carefully. Usually it contains information about materials that can be worked with.

What else to pay attention to

In such a matter as sewing leather on a machine, there are no trifles. Therefore, we recommend that you carefully select your tools, such as needles and threads. You cannot use the first ones you come across: you can hopelessly ruin the product.

Needle selection

Stores sell special needles for working with leather. They are suitable for sewing from artificial and natural materials.These needles are quite strong and do not tear or tighten the skin.

Important! Buy not one or two needles, but a set. Although durable, they break in thick areas.

Thread selection

The first rule of any sewing is that the threads and needle must match each other. This is a universal recommendation. However, leather is a capricious material, so when working with it it is important to consider the following points:

- nylon threads are suitable only for manual work with leather products (mainly for repairs);

- Do not sew leather with cotton threads;

- threads made of nylon or polyester are ideal;

- Excessively thick thread is often used for decoration.

Useful tips

Working with this material is not easy. But we remember: in skillful hands, any business succeeds. Therefore, there is no need to be discouraged. It is better to be patient and read the advice of craftswomen before you sit down to work.

Here are the most useful ones:

- Working with leather is irreversible. This means that the product cannot be sewn and then ripped apart. This causes the material to tear and lose its presentable appearance. We recommend that you prepare properly: immediately place the required foot and needle, threads, and carefully cut the fabric.

- There is no need to neglect test sewing. One line on a piece of leather is enough to understand that the machine is working properly.

- The simpler the model, the better it will look. This rule applies to items sewn on home sewing machines. Complex lines, flounces, ruffles not only overload the product, but also spoil its appearance: sewing such details carefully at home to thick material is almost impossible.

- Making leather products is impossible without glue. PVA, rubber glue or Moment will do. It is important that it is not too liquid. The golden rule for this kind of work: it’s better not to add glue than to smear it all around.A special tape with sticky sides can be an excellent alternative to glue.

- Buttons must be sewn together with a subbutton (it is placed on the wrong side).

- To ensure that punched buttons look beautiful and do not spoil the leather, non-woven fabric is used when installing them.

It is possible to sew a beautiful leather item yourself. This does not require special knowledge. The main thing is to take into account the nuances of such sewing and remember that working with leather requires patience.

0

0