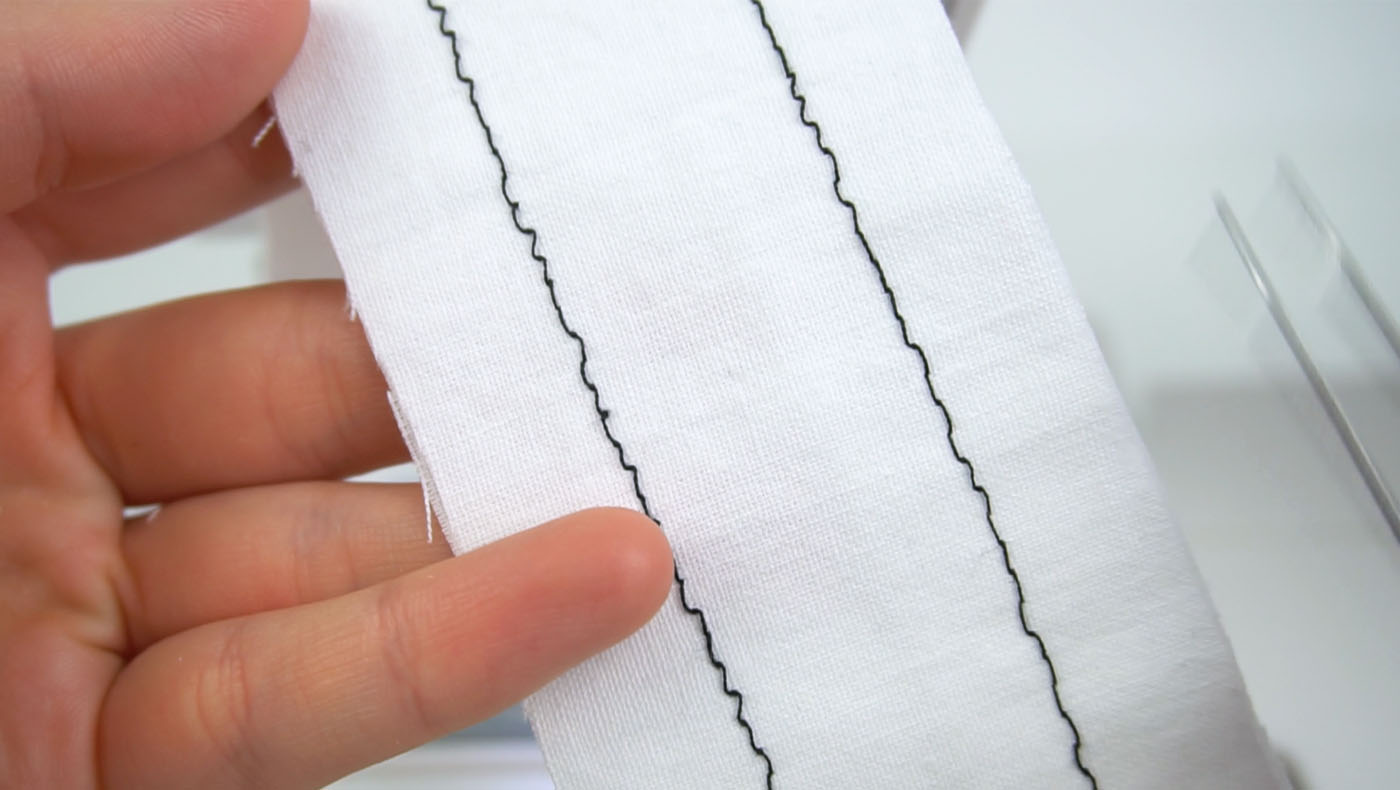

It happens that the bottom line begins to loop while sewing, and the stitches turn out sloppy. There may be several reasons for this phenomenon, and it is not always the case with the lower thread. In this article we will talk about the most common problems that cause such trouble.

Why does the lower thread loop in a sewing machine?

Sometimes it happens that the stitching turns out uneven at the very beginning of sewing. But it often happens that the machine worked well for a certain amount of time, and then the seam “looped.” Before you do anything, it is important to understand why it happened.

Causes

They can be quite serious or quite ordinary. Let's note the main ones:

- Low thread tension. If the stitching immediately loops, most likely you did not tighten it enough when preparing to sew. If the seam begins to loop during operation, the thread may have loosened on its own (this often happens due to a faulty tensioner or poor quality thread).

- The thread is not threaded correctly.

- Incorrect machine settings: as a rule, the problem lies in problems with the shuttle stroke.

- The lower and upper threads are different in thickness.

- The thread slows down while moving in the stitch. This occurs when excess thread is created. It does not have time to tighten in time, and loops form.

- The presser foot does not work properly or there are nicks on the needle plate.

- The upper thread tension spring has become loose. Because of this, a surplus is also formed, which does not have time to be consumed during sewing.

- Defects on the surface of the hook or bobbin case. The thread seems to be stuck and does not move as smoothly as required. Because of this, a loop is formed.

- The tensioner plates are not clamped (fully or partially).

- Car breakdowns. For example, the shuttle or the bobbin on it, the needle, or the regulators may become completely unusable. In short, the breakdowns are different, and each of them needs to be dealt with individually.

How to fix the problem

If you notice that the stitching is looping, you need to stop working and try to find out the reason. Further actions depend on this.

The algorithm is as follows:

- Check tensioner settings. See if the thread is loose and adjust the operation of these elements. Don't forget to check that the thread is threaded correctly. It is important to look at both the top and bottom threads.

- If the first point does not work, remove the shuttle and inspect it. Check the needle, the threads themselves, look at the upper tensioner. If any defects are visible on the hook, bobbin or needle, replace them.

- Pay attention to the threads. If the thickness is different, you need to replace one of them.

- Try lowering the presser foot. If it does not clamp the fabric enough, the seam will loop.You can change the part yourself (this is not always required, sometimes you just need to adjust its operation) or contact a specialist.

- If defects appear on the needle plate, it must be replaced with a new one.

- It is useless for a person who does not know the structure of a sewing machine to look at the springs and plates themselves. It is better to take the device to a workshop, where they will not only replace faulty parts, but also carry out a full diagnosis.

If it seems that the machine is seriously broken, it is better not to risk trying to repair it yourself, but to immediately take it to a workshop.

Prevention: what to do to prevent the bottom line from looping

As a rule, problems arise due to our careless attitude towards the machine and gross violations of operating rules. We simply forget that any household appliance requires attention.

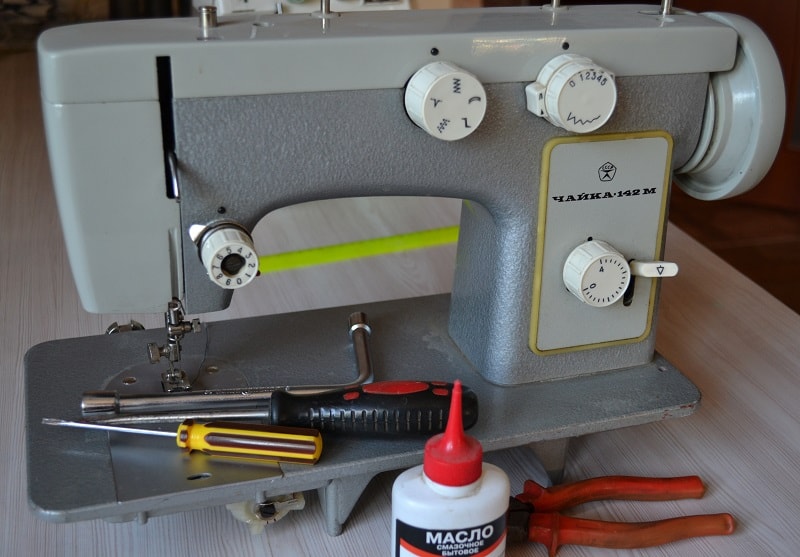

It is important to lubricate the machine in a timely manner and clean it of debris, dust, fabric and thread residues. It is important that it is in a dry place (in a room with high humidity, metal parts quickly become unusable).

Do not forget about the operating rules:

- before turning on for the first time, you need to read the instructions, and not start sewing at random;

- thread the same threads that correspond to the thickness of the fabric and the needle;

- check the serviceability of elements such as the hook, needle, tensioners, presser foot, needle plate, and change them in time;

- Before each sewing, check the thread tension and make test stitches.

It seems that the recommendations are elementary. But not everyone follows them. However, experienced craftswomen know: if you want sewing to be enjoyable, you cannot neglect these tips.

Useful tips

Sewing responsibly. Not only the success of the entire work depends on this, but also the service life of the machine.

For example, it is recommended to clean the device at least once a month (if you use it regularly). It is better to do this with a soft brush or cloth.

The machine should be lubricated with special oil (you can buy it at sewing equipment stores). It is important not to overdo it: if there is too much oil, there is a risk of staining the material or your hands while sewing.

Do not neglect checking the machine before work. It is not enough to simply plug it into a power outlet. It is important to check how the threads are tensioned and whether the needle is positioned well. Always select your thread and needle carefully (check the label for what is usually marked). If the fabric is thick, but the needle and thread are thin, you can not only ruin the product, but also break the machine.

Don't be lazy and make a test stitch before the main one. It’s better to use the same material you plan to work with. This procedure takes no more than two to three minutes and helps to spot problems in time.

Do not try to resuscitate the machine if it is obvious that it is broken. This can only make the situation worse. It is cheaper to entrust the solution to serious problems to a professional.

0

0

The bottom thread of the old Singer machine began to loop. I sinned on the shuttle - it rocks. But it turned out that the reason was in the thread take-up: the spring had weakened. It took a long time to find this reason.I wanted to throw the machine away, but I couldn’t bring myself to sell it for scrap, because she’s my friend and always sews superbly. I have an electric machine, but it’s very capricious and sometimes I want to slam it on the floor. Now my Singer is working again after repairing the thread take-up. I am writing for those who have not yet parted with Singer.

These cars are forever. At one time I sold my grandmother’s Singer, and now I really regret it. They are like dogs - loyal all their lives.