Any equipment can break down sooner or later. The sewing machine is no exception. In this case, both old units and modern devices can break down. What problems are particularly common, and what to do in case of a breakdown? We will talk about this in the article.

Why doesn't the sewing machine sew?

So, the machine broke down, work stopped, and it’s completely unclear what to do next. First you need to calm down. Most likely, nothing critical happened, and the device can be returned to working condition.

Before taking any action, it is important to understand under what circumstances the breakdown occurred and determine the possible cause. Then it will be clear what to do next: take the machine to a specialist or repair it yourself.

Possible causes of malfunctions

So, the fault has been identified. Based on this, the cause can be established. For example, the thread does not feed in the following cases:

- the screw that holds the bobbin is beveled;

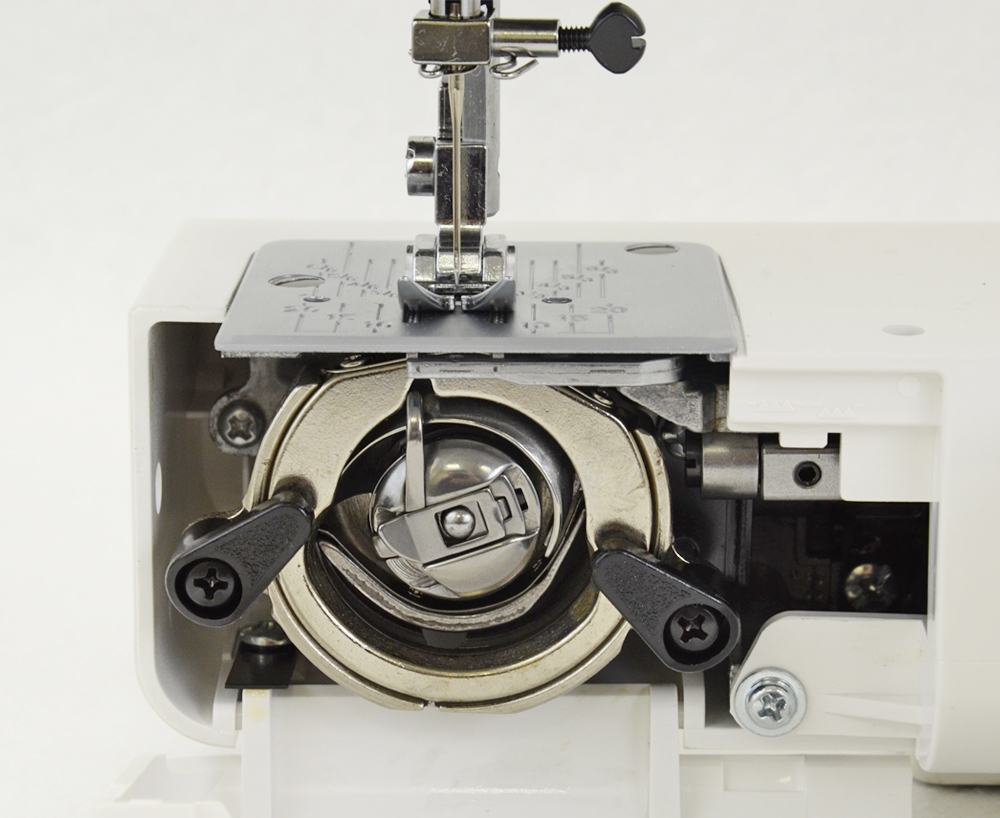

- the tip of the shuttle has worn out, another option is that the settings for this part have gone wrong;

- nicks appeared on the bobbin case;

- the needle-function mechanism is configured incorrectly, for example, too high or too low;

- The needle bar and the lower part of the machine do not work synchronously.

The second common cause of breakdown is a malfunction of the unit that is responsible for guiding the needle. This happens when the fabric is too thin and the needle is too thick, and vice versa - due to an incorrectly chosen needle or its breakage.

The machine will move jerkily if the gap in the needle plate is worn or widened. In this case, the area of tissue around the puncture rises along with the needle and the shuttle does not work correctly.

Failure to synchronize individual elements of the machine, for example, the slats and needles, entails tightening of the fabric and breaking of the thread. The same thing happens if threads of different widths are used at the same time when sewing (if the bottom one is too thin and the top one is very thick). Slight differences in thickness are not dangerous.

Remedies

These problems are solved in different ways. In some cases, you can handle it yourself, but there are situations when you have to give the machine to professional craftsmen.

So, if the thread does not give in, is too tight or, conversely, weak, you can check how correctly the bobbin is installed. You can track and adjust the thread tension using a special screw (it is installed next to the shuttle mechanism). After troubleshooting, it is recommended to make a test seam to check the functionality of the machine.

If the corner guide is beveled or moved to the side, it is recommended to check the thread tension. It should not be overtightened.

When the bobbin thread does not catch and the line appears choppy, check the hook. It may need to be cleared of any wound threads.Another variant of shuttle malfunction is manifested by sagging loops on the inside. This means that you need to replace the shuttle or its individual elements (some parts may oxidize or wear out).

The needle should be replaced if the fabric begins to jam under the bottom panel. Most likely, the needle has become dull or bent.

If the machine stops working and does not turn on at all, you will have to take it in for repairs. Perhaps everything is not so scary, and the master will be able to revive her quickly enough.

Prevention: what to do to prevent the machine from breaking down

Any device will work for a long time if it is used correctly. A sewing machine (especially modern models) is a complex mechanism that requires careful handling.

Experienced craftsmen give several recommendations for proper operation:

- The machine must be placed on a stable table with a flat surface.

- You should pay attention to the needle size and thread thickness. It is necessary that they match the fabric (when purchasing the material, you can check with the seller for this information).

- You need to work according to the instructions, especially when it comes to threading spools of thread. Do not disturb the sequence when pulling the threads.

- Before starting work, make a test seam to ensure that everything is functioning correctly and not to damage the fabric.

- Buying threads is a very responsible undertaking. It is recommended to choose smooth and even ones that will not fluff up or wrap around the shuttle.

- The machine needs timely lubrication. If modern models have a built-in timer, then in older mechanical devices you need to monitor this indicator yourself. On average, lubrication is required every 5,000 operating hours.

- Check your needles.Parts that are crooked, dull, or simply worn out must be replaced in a timely manner.

- You should not expect that it will “go away on its own” if there are any errors in the operation of the device. It is better to eliminate them immediately so as not to spoil the fabric and not lead to serious damage.

A sewing machine is a complex mechanism that can sometimes malfunction. It requires careful handling and timely replacement of removable elements. However, failure does not mean that the device will have to be thrown away. In most cases, everything is resolved quite simply.

1

1