A handbag is considered an indispensable item in a woman’s wardrobe. Their fabric should be quite durable and strong, as well as easy to care for.

A handbag is considered an indispensable item in a woman’s wardrobe. Their fabric should be quite durable and strong, as well as easy to care for.

To create an accessory, all kinds of materials are used: natural and synthetic.

Split leather panels have become one of the most popular consumables in the production of bags.

Features of split wood materials

Split leather is not leatherette! Their made from natural skins, therefore classified as leather. They are excellent raw materials for haberdashery products.

What is a split

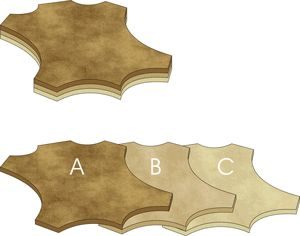

When tanning animal skins, several layers of leather are obtained at once. One of them is split leather panels. They appear as a result of processing and dividing the skin into layers, as well as removing the surface ball.

The thickness of animal skins varies. The number of layers obtained during sanding depends on specific parameters. The quantity varies from three to six pieces. These balls differ in their properties and ultimate purpose of use.

The layers are divided like this:

- facial;

- average;

- mezdrovy (it is also called bakhtarmyany).

The first one is used to produce the highest quality leather.. It has a natural pattern.

The second (this is the split leather part) also goes to the skin. But it is already lower in quality. For strength, an adhesive coating is applied to the layer. From this part They also produce split velor. Shoes, mittens and clothing for workers are made from it.

The third layer is intended to obtain the technical substances of collagen products. For example, such as gelatin, glue and others.

Manufacturing process

Natural split wood is obtained from cattle. To make high-quality leather bags, calf leather is used.

The skin of different animals, like the layers, has various properties. Cow and ox hide material is one of the best types. It is odorless, durable and beautiful on the outside.

Visually, you can immediately notice the similarity of split leather with suede or velor. Having treated it with chemicals, the material will be difficult to distinguish from real leather. Since this is an inexpensive material, it is used in the manufacture of economy class bags and shoes.

Production technology

- After the skin is removed from the animal and tanned, a fairly dense layer of several millimeters is obtained. In its natural form, such thick skin is not used for making bags. It is very difficult or impossible to make any object from such a wide layer (4–5 mm). Therefore, take the following steps.

- At first the skin is divided into two layers. After dividing, bags cannot be made because the material is still considered raw.

- The next step will be his impregnation with a thin polymer layer to create a protective film. It protects against dirt, wear and damage.In this form it is very easy to care for the products. You can wipe the white bag with a damp cloth and the surface will become clean. Another advantage of polymer coating is the decoration of the material.

Important! A well-made bag will have a simply chic appearance.

- Next manufacturers remove surface imperfections (scratches, folds, etc.) by grinding and embossing. The first method is to press the skin with a heated steel plate, and this helps to smooth the material. The second is that brand logos, etc., are pressed onto the top.

If the split wood is polished, it will turn out identical to the outside. However, there will be no porous structure. Using a press reduces strength. The thickness of the layer on the skin is different everywhere due to the unevenness of the animal’s skin. Therefore, it is often necessary to glue the split wood in order to maintain the standard parameters of the raw material.

Advantages and disadvantages of split leather

Compared to artificial leather, the middle layer of animal skin is more durable and of higher quality.

Advantages

- The cost of the material is much cheaper than that of leather.

- Wear resistance is higher than that of artificial material.

- Very easy to process, when polished it becomes similar to the front side.

Flaws

- The natural material has good water resistance. Split leather does not have this feature due to the surface being damaged by a sharp knife of the equipment. Therefore from it It is not worth sewing outerwear and shoes, such products will get wet or will not withstand precipitation and will fall apart.

- Doesn't look very attractive from the outside.

- Split wood is a non-breathable material. Only the top layer of the animal's skin is porous.

- A hot press reduces strength.

Considering the advantages and disadvantages, experts consider this material to be one of the most suitable for making bags.

0

0