High technologies have long become commonplace. Sometimes we don't notice them. Of course, when it comes to modern gadgets or technology, most of us admire the wonders of scientific progress. But is it only in electronics and large machines that the power of the human mind manifests itself? Not at all.

Synthetic materials from which some products for personal or home use, sports or professional activities are made are sometimes also prominent representatives of high technology. For example, neoprene. The name may be unfamiliar, but we come across things made from this non-woven fiber every day. What is neoprene and why is it popular? This will be discussed in the article.

Description of material

Neoprene appeared at the beginning of the twentieth century. In 1930, scientist Wallace Carothersc from the popular company DuPont (its specialization is the production of polymers) patented it.

Note that neoprene did not immediately become the material we use now.Initially it was called “Dupren”. It was impossible to use it anywhere other than the production of shockproof and moisture-resistant coatings. It emanated a terrible smell, which was overcome only after 7 years of active work on this problem..

What does it look like?

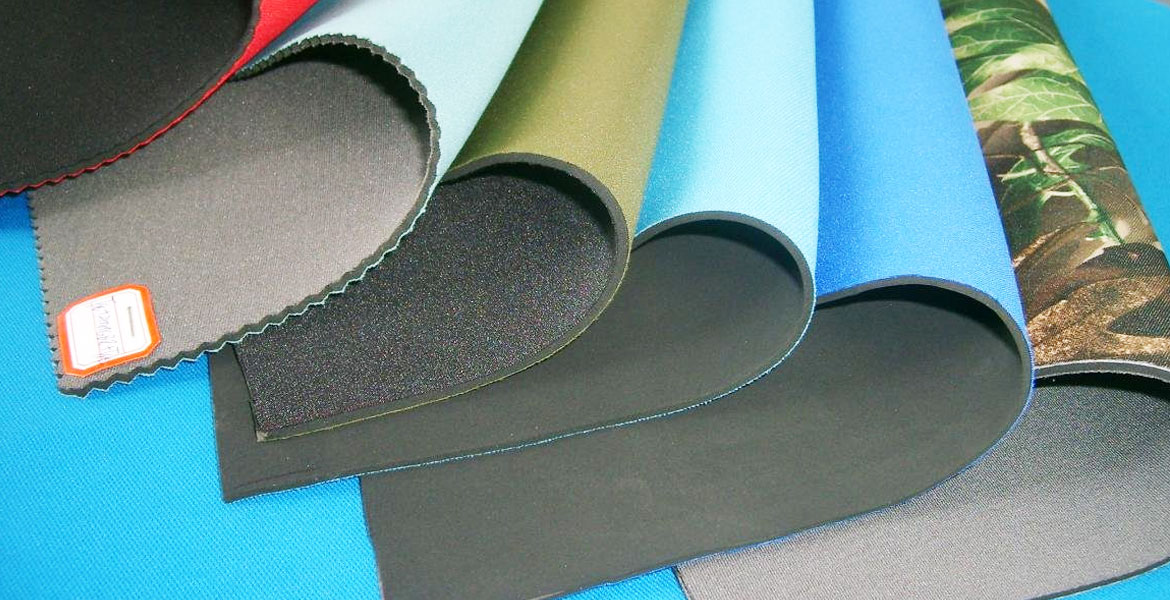

Today Neoprene is an elastic material that is odorless. It's porous. Its structure is quite unusual: many tiny rubber cells filled with air bubbles. Thanks to this, it stretches and is not susceptible to mechanical stress (it is difficult to tear or deform).

In its pure form it is black, less often – gray or brown. To give a neoprene product a presentable look, the top layer of the material is covered with colored viscose, cotton, polyester or lycra.

Composition and strength characteristics

By the way! The second name for this material is foam rubber. It consists of so-called chloroprene rubber.

Neoprene incredibly durable. To spoil its appearance, you will have to try very hard. Unlike other rubber materials, it is not flammable. Resistant to cold and heat (the quality characteristics of products made from it will not change at ambient temperatures from +90 to -55 degrees).

Production technology

The raw materials for its production are petroleum products, in particular, chloroprene. Polychloroprene chips are created from it. It, combined with black pigments and foaming agents, is the basis of the future neoprene.

These ingredients are mixed. The result is a viscous mixture that looks like black dough. It is sent to an oven to create foam rubber. The output is a sheet several centimeters high. Only on one side is it smooth.This layer is cut, like a sponge cake, into smaller sheets with a height of 0.5 to 10 mm. At this stage they are brittle. That's why To increase strength characteristics, thin layers are laminated.

As noted above, in order to make the material attractive in appearance, it is covered with a variety of fabrics. To make it more heat resistant, A titanium or polymer coating is applied to the surface of neoprene.

Advantages and disadvantages of fabric

Neoprene has more than enough advantages. So, among the main ones we can note:

- beneficial effect on the human body. No matter how surprising it may be, but this synthetic can heal. It fixes organs, muscles and tissues in the required position, for example, in case of injuries, improves blood flow in the epidermis, warms up, and has a light massage effect. In addition, neoprene removes toxins and speeds up metabolism;

- like any rubber, This type of rubber is completely waterproof. Neoprene is also resistant to oils, salt water, and chemicals;

- it protects against injury due to its porous structure;

- does not accumulate static electricity;

- does not cause allergic reactions even in people prone to them;

- a product made from this fabric retains its shape perfectly, it is soft, light, flexible, and does not wrinkle at all.

Despite such obvious advantages, neoprene has disadvantages:

- it is completely airtight. That's why You can’t wear clothes made from it all the time (the permissible norm does not exceed 2-3 hours a day). It creates a sauna effect, due to which, with prolonged exposure, blood pressure levels may increase, heart rate may increase, and skin irritation may appear;

- the material takes a long time to dry, even if bright sun rays fall on it;

- it requires special care (this will be discussed below);

- neoprene does not withstand the effects of alkali and acid. Even if these substances get a little on the surface, a hole will appear.

By the way! It is precisely because of the existing shortcomings that children’s clothing is not made from this fabric at all.

How is it different from other synthetics?

This material is unusual. Unlike his synthetic “colleagues”, he is not an interweaving of polyurethane threads, but looks like porous rubber layers.

In addition, unlike other materials, the scope of neoprene is very limited. It is rarely used for everyday wear, but is actively used in other areas.

Types of Neoprene Material

This fabric has several classifications. Manufacturers take this information into account when choosing material for a particular product.

Based on density level, the following types are distinguished:

- Soft – fabric with the lowest density. It stretches, is quite soft and thin, but wears out quickly. Suitable for sewing sports uniforms. It is considered the most comfortable to wear of all types of neoprene.

- Medium density. Its density is average. This fabric is more durable and wear-resistant, but not as comfortable. It is used when sewing special uniforms, for example, clothing for rescuers and firefighters.

- The most dense fabric is high density. It is rigid and is used when sewing diving equipment.

By the way! The density of neoprene can be determined independently by the porosity of the material: the fewer air bubbles, the denser the fabric.

Another classification is by purpose. Here the thickness of the canvas is taken into account. So, there are 6 types:

- LS – soft fabric. Her the surface is silky and pleasant to the touch. The material stretches well, and therefore is used for sewing everyday clothes (for example, waterproof raincoats). Another area of application is the manufacture of suits for amateur diving.

- S – dense and elastic fabric. This fabric makes excellent suits for deep-sea diving, bandages, belts, and upholstery elements.

- HS - the cells of this material are very dense and not flexible at all. It is used for upholstery of sports equipment, sewing uniforms for cyclists, hunters and outdoor enthusiasts in extreme conditions. In addition, it is used for the production of tourist equipment: tents, backpacks, awnings.

- HHS - absolutely non-elastic material. Dense and elastic. Used in the manufacture of protective elements, as well as in the production of footwear.

- NF – thick fabric. This is a fire-resistant material that is widely used in making protective clothing for firefighters.

- W – white neoprene. Its feature is spraying with an antibacterial effect. Widely used for the manufacture of medical goods: orthopedic shoes, bandages, overalls for doctors.

What is made from it?

Neoprene is indispensable in completely different areas:

- for the production of diving equipment (primarily wetsuits);

- in tailoring clothes for water sports (surfing, rafting and others);

- in the manufacture of everyday goods (cases for phones and tablets, beach shoes, upholstery for sports equipment);

- in the production of medical goods;

- in tailoring clothes for professional sports;

- in the production of protective clothing and its individual elements.

About 10 years ago neoprene began to be used when sewing trendy clothing collections. Of course, these things are very original and unusual, but they are in demand and have found their “fans”.

Reference. The very first collection, which was presented first to the fashionable elite, and then to ordinary people, appeared in 2009. It belongs to designer Nicolas Ghesquière. Since then, the production of stylish neoprene clothing has not lost popularity.

Nuances of care

Foam rubber is a special material. Manufacturers It is not recommended to wash and dry products made from it yourself at home. It is better to use dry cleaning services.

If this is not possible, then you should adhere to the following recommendations:

- The product, regardless of its purpose, should only be washed in cold water. The temperature should not exceed 30 degrees. Machine washing is strictly prohibited (even a delicate cycle can permanently damage the material);

- Do not use powdered cleaning products, or those containing aggressive or bleaching agents. The best option is soap or liquid gel;

- any rubber, regardless of its characteristics and manufacturing methods, does not absorb water at all. Therefore, you need to wash each side in turn: back and front;

- It is not recommended to rub brushes and washcloths, even products made of seemingly durable neoprene;

- Do not forget that this material takes a long time to dry. That's why It is recommended to dry it exclusively in ventilated areas or in the open air. However, direct sunlight should be avoided;

- During the drying process, it is recommended to turn the item from the wrong side to the right side, and vice versa. Thanks to this procedure, drying will be quick and trouble-free;

- If a neoprene product is damaged (for example, a wetsuit or bandage), it does not need to be thrown away. It is better to give it to a specialist who, most likely, will be able to repair it (you can contact a shoemaker).

0

0