Synthetic fabrics have firmly entered the life of modern man. Insulation in winter clothes, tracksuits, underwear, chic curtains and soft blankets - all this and much more is now made from artificial materials.

Synthetic fabrics have firmly entered the life of modern man. Insulation in winter clothes, tracksuits, underwear, chic curtains and soft blankets - all this and much more is now made from artificial materials.

Buy fleece - get polyester? It often happens that when we pick up a soft, new thing, we know for sure that it is fleece. But the label says 100% polyester. And this discrepancy causes misunderstanding. It is worth closing the issue with 100% polyester fleece, that is, it will not be possible to determine the difference since the raw materials are almost identical. But it is worth saying that it is a secondary raw material after polyester.

Polyester (polyester) is a synthetic material that resembles wool in appearance, but has a tactile feel like cotton. In addition to fabrics, it is used as a filler in toys, furniture, pillows and blankets. It is produced from petroleum products.

Polyester and fleece have differences from natural fabrics:

- strong and durable;

- resistant to physical influences;

- are not afraid of insects;

- are light in weight;

- easy to care for;

- are easy to wash and dry quickly, since polyester threads do not accumulate liquid;

- do not absorb odors;

- more affordable.

When polyester is mixed with other fabrics, raw materials with new qualities are obtained:

When polyester is mixed with other fabrics, raw materials with new qualities are obtained:

When mixed with polyamide, it produces fabric with characteristics similar to silk. The fibers hold their shape well and repel moisture. Used for sewing women's underwear. A mixture with elastane or spandex produces a durable, highly stretchable material.

Most often, hosiery, gloves, and tracksuits are made from it. A cotton blend is used to sew bed linen. This compensates for the disadvantages of cotton. The fibers dye well, do not fade, and practically do not wrinkle. The combination of polyester and viscose is also popular.

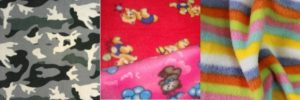

Production and types of fleece

Polyester knitted fabric is passed through a machine equipped with rollers with tiny hooks. These hooks lift tiny loops from the fabric, leaving the base of the fabric intact. The result is a pile with a huge number of breathing pores. This is how the material turns out, which received the name “fleece” for its qualities, which is translated from English as “sheepskin”. It was invented in 1979.

Fleece undergoes several mandatory treatments:

- Anti-pilling – to prevent the formation of pellets;

- Antistatic;

- Water repellent;

- Flammability reducing treatment.

Products made from this fabric often consist of more than one layer. In the case of a two-layer layer, the upper part serves as protection from wind and/or snow, and the lower part maintains a comfortable temperature. The most common name for this material is bipolar fleece. The three-layer version is called "windblock": two layers of medium-thick fleece and a special membrane between them.

Products made from this fabric often consist of more than one layer. In the case of a two-layer layer, the upper part serves as protection from wind and/or snow, and the lower part maintains a comfortable temperature. The most common name for this material is bipolar fleece. The three-layer version is called "windblock": two layers of medium-thick fleece and a special membrane between them.

The main characteristic of this fabric is large density range, from 100 to 500 g/m2. Sweatshirts, warm shirts and similar relatively light items are made from material with a density of up to 200 g/m2. Denser raw materials are used to produce insulation for outerwear or independent products.

Let's summarize. Fleece is a derivative of polyester. Pure polyester is a material with increased strength, lightness and hydrophobicity. It is excellent for the production of linen, curtains, and bedding.

All the positive properties of polyester are inherited by fleece. In addition, the fabric has an increased ability to retain heat and allow air to pass through, which the original material lacks. Such qualities make it an excellent material for production of tourist, sports and winter outerwear.

0

0