Satin is widely used for sewing bed linen, curtains, clothes and bedspreads. The popularity of the material is explained by its beauty, color fastness, lack of shrinkage after washing, and affordable cost. It is soft to the touch and has the same shine as silk.

Satin is widely used for sewing bed linen, curtains, clothes and bedspreads. The popularity of the material is explained by its beauty, color fastness, lack of shrinkage after washing, and affordable cost. It is soft to the touch and has the same shine as silk.

In addition, satin underwear does not cause allergic reactions or skin irritation in humans.

Satin density

According to some characteristics, satin is divided into several types. According to GOST, the density of fabric is considered to be the number of interwoven threads in 1 cm2.

According to some characteristics, satin is divided into several types. According to GOST, the density of fabric is considered to be the number of interwoven threads in 1 cm2.

- Regular satin has a density 85–130 weaves in 1cm2. Painted using pigment printing and mercerized. This method of processing fabric gives it additional strength, shine, and prevents lint from rolling off on the surface of the fabric.

- The printed material is denser - up to 170 weaves in 1 cm2. The reactive printing method is used to create a pattern on the canvas.

- Printed satin has a second name – coupon.This method of applying a pattern to a product allows you to create bedding with a pattern that is the same in style but different in size for pillowcases and sheets with duvet covers. The density of coupon sateen is the same as that of printed satin.

- Jacquard is another type of fabric with a thread density 170-220 in 1 cm2. It is double-sided, the pattern is created with colored threads during the fabrication process. It looks like the finest tapestry. In this case, the main background has a matte base, and the elements of the pattern are shiny, located, as it were, below the main background.

- Mako-satin is the densest type of fabric, having 1 cm2 over 220 threads.

Important: for the production of dense types of satin, cotton fibers of the smallest diameter are used. The fabric obtained from them is very light, but at the same time has increased strength.

Density of satin for bed linen

Lovers of quality bed linen are not bothered by the fact that the cost of satin is higher than the cost of many other cotton fabrics. Advantage is given to the strength and beauty of the canvas, which retains its qualities for a long time.

When choosing satin bedding sets, you should still pay attention to the material density marking according to GOST. Not all types of satin are recommended for use in bed linen. The highest quality and most durable bedding is made from satin with a number of interwoven fibers from 140 to 1 cm2 and higher. These are printed and coupon materials, jacquard and mako-satin.

Important: sometimes the thickness of the fabric on the packaging of the bedding set is not indicated by the number of weaves of threads on 1 cm2, but in grams. Higher quality satin bed linen has a fabric density of at least 120 g per 1 m2.

The thickness of satin depends on the number of weft or warp fibers on 1m2 fabrics. Satin is an unequally dense fabric due to the way the threads are interwoven (at a ratio of 1:4 - weft thread to warp threads). Therefore, to determine the quality of a material, the concepts of linear and surface density are used.

Read a detailed article about what fabric density is best for bed linen.

Linear density

The shape of the fabric cell and, accordingly, its strength and elasticity in the longitudinal and transverse directions depend on the ratio of the density of the weft threads and the warp. Even with the same number of threads in both directions, their thickness can be different, which affects the thickness of the fabric. The ratio of the actual number of warp threads to the number of threads that could be located on a piece of fabric of the corresponding length at maximum filling is called relative or linear density.

The shape of the fabric cell and, accordingly, its strength and elasticity in the longitudinal and transverse directions depend on the ratio of the density of the weft threads and the warp. Even with the same number of threads in both directions, their thickness can be different, which affects the thickness of the fabric. The ratio of the actual number of warp threads to the number of threads that could be located on a piece of fabric of the corresponding length at maximum filling is called relative or linear density.

Surface density

The surface area of any tissue is usually considered to be the ratio of its mass to a unit area. In this case, mass is measured in grams, and area - in square meters. So, for satin used for sewing bed linen, the surface density should be 120 – 145 g/m2.

This value depends on the linear density, the method of weaving the threads, and their diameter. Thinner tissues have less superficial fatness.

Advice: The surface density of a material can be determined using the calculation method by weighing the material and calculating its area.

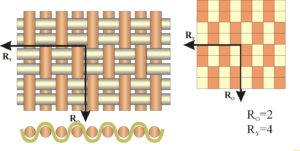

About the interweaving of threads

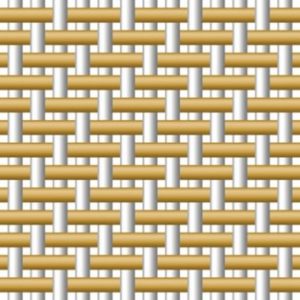

This beautiful, durable cotton fabric got its name thanks to a special way of weaving threads, which is called satin.

This beautiful, durable cotton fabric got its name thanks to a special way of weaving threads, which is called satin.

To create a fabric with this name, two types of threads of different densities are used: the base is made up of dense threads of a larger diameter, and twisted threads of a thinner section are used to create the front side.

With satin weave, there is one twisted front thread for at least four warp threads. As a result, a smooth shiny surface is formed on the front side of the fabric, silky to the touch, with a diagonal weave pattern.

The stronger the weft threads are twisted, the brighter the shine of the front surface and the higher the strength of the satin fabric. The reverse side of the material is matte in color, soft, and resembles flannel in tactile sensations.

Caring for satin bed linen

Satin bed linen can last for many years without losing its external qualities and strength. The main condition for this is compliance with the rules for caring for items made of satin fabrics:

- Satin linen should only be washed inside out.

- The optimal water temperature for washing should be no higher than 40°С.

- Do not wash colored satin items using detergents that contain bleaching components.

- To remove stains, use products recommended for satin fabrics. Contamination must be treated before the laundry is placed in the washing machine.

- Satin bedding is not recommended to be washed with items made from other fabrics. This can take away its shine and softness prematurely.

- It is better to iron slightly damp laundry from the wrong side.

0

0