Silk is one of the most beloved and sought-after materials. It is light, durable and has a pleasant tactile sensation. It is used to make high-quality clothing, accessories, home textiles and much more.

Silk is produced both artisanally and industrially. First, the caterpillars are raised and fattened silkworm. Pafter the formation of cocoons of them get the threads and then weaving method — finished canvas.

Natural silk production technology

This is a long and complex process that requires maximum scrupulousness.

A little history

The fabric was first produced in Ancient China, in the fourth millennium BC. e. The technique of its manufacture was kept in the strictest confidence. Its disclosure was tantamount to treason and was punishable by death. Since China remained a monopoly for a long time, the cost of material was very high. The exchange of a pound of silk for a pound of gold was considered equivalent.

After more than three thousand years, the Japanese were the first to acquire production technology, then the Arabs and the Byzantine Emperor Justinian.And during the Crusades it spread throughout Europe.

Raw materials for silk extraction

It is produced by the silkworm. The most valuable representative of this species is Bombyx mori, which is artificially grown and does not live in the wild. Only it forms a cocoon from which the highest quality Mulberry silk fiber is obtained. Having hatched from the cocoon, butterflies do not fly and do not see anything. They live only a few days, which, however, is enough for mating and breeding. One female can lay up to 500 eggs over five days.

Silkworm eggs are small in size, 500 pieces weigh no more than five grams. The caterpillars hatch from the cocoon on the 10th–12th day. The required number to produce 1 kg of silk is about 6 thousand individuals. To transform into a “pupa,” silkworms consume mulberry leaves day and night without stopping. The development cycle from larva to adult silk-reproducing caterpillar is approximately a month. All this time it is necessary to strictly follow the established feeding system for silkworms.

aurahazefarm

Having increased their mass by 10 thousand times, each begins to form a cocoon with the help of the salivary gland. The shell is formed within three days and has a light yellow color and a glossy tint.

@silkwormcyprus

The finished cocoons are collected and further processed. The main thing is to do it on time.

Getting threads

The fiber that makes up the cocoon contains fibroin (75%) and sericin (25%). Fats, waxes and minerals are also present in small quantities.

The process of obtaining a thread includes several stages:

- Boiling: cocoons are thrown into hot, even boiling water. This is done to wash out the sericin and deglue the threads.

- Removing excess moisture.The silk fiber that makes up the cocoon is thinner than human hair. And in length it reaches an average of one and a half kilometers. When wet, it is easy to tear, so it is necessary to remove the water at least partially. For example, Thais who produce silk by hand use rice for this purpose. This product, placed in a raw silk mass, perfectly absorbs liquid.

- Pulling. A thin thread is wound on a special device - a spool. Most often, the fiber is folded several times to obtain the desired thickness.

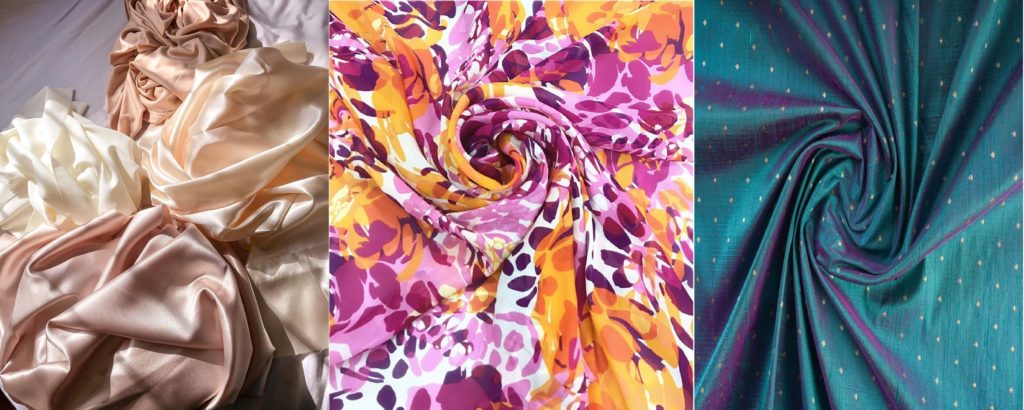

- Bleaching and dyeing. The color of natural raw materials is yellow, so it is first bleached with hydrogen peroxide, and why it is painted. The structure of the silk thread allows it to deeply impregnate the fabric, as a result of which the color is preserved for a long time.

@hemanth.rockzzz

Fabrication

In order to become matter, the threads must enter the loom. Silk is woven using both manual and industrial machines. In a factory, the process takes several times less time than in artisanal production. With full automation of the process, productivity can reach 100 kg of products per day.

The finished fabric is usually subjected to additional processing, namely:

- revitalization - treated with a solution of vinegar essence to obtain shine and rich color;

- decatification - steam is applied under high pressure to prevent shrinkage.

@stariiee, @chinasilkfabric, @neev_by_vibhutikabra

Technologies for the production of natural silk have remained almost unchanged over time. This process still remains complex and time-consuming, so the price of finished products is not the most affordable. However, this does not stop consumers who value the quality of the product above its cost.

1

1

from the point of view of the stylistics of the Russian language, everything is very sad: the coordination of parts of speech, grammar... and as you might guess, putting commas in these very places... the article looks like a combination of the translation of several paragraphs (poor translation) and the author’s attempt to compress the amount of information provided in the rest.. hard to read.

but it could turn out to be a pleasant and interesting article