Yarn obtained from milk has become a worthy alternative to natural material made from animal hair. Next, we will consider its features and manufacturing technology.

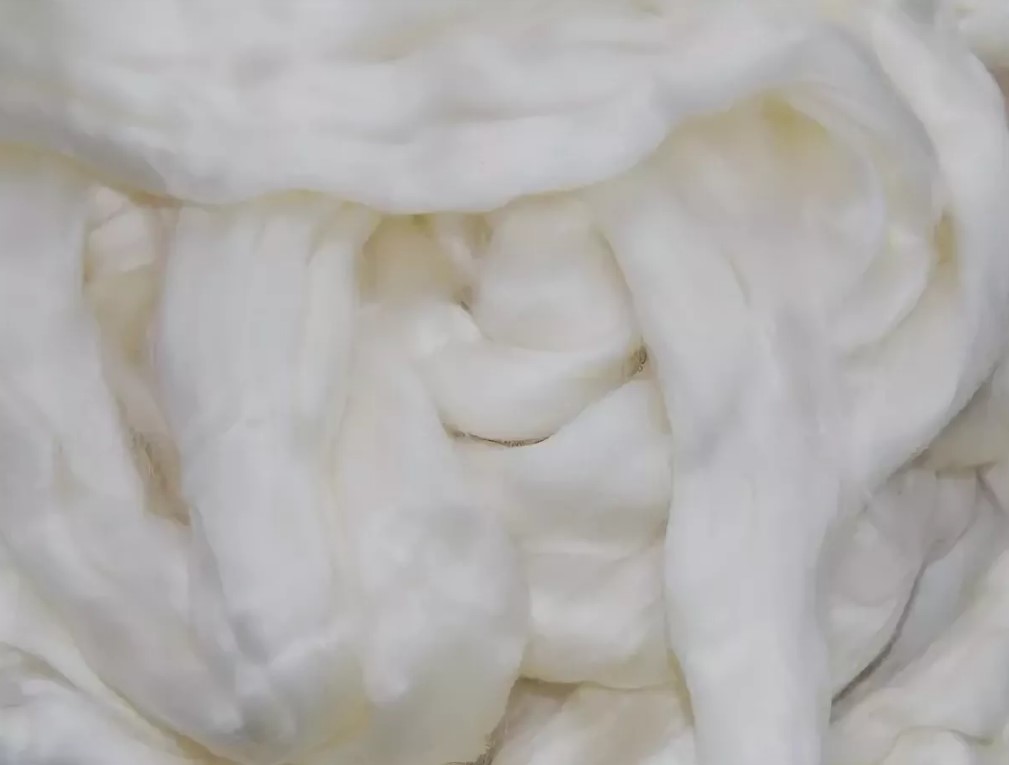

Yarn from milk

Many people have already appreciated yarn made from milk. It has a natural moisturizer and has a beneficial effect on human skin, relieves allergic reactions and even smoothes out fine wrinkles.

Products made from milk wool have become a godsend for people with sensitive skin. The material is lightweight, voluminous, quickly absorbs liquid and does not fade.

Reference! Due to the good ability of the yarn to be dyed even at low temperatures, a wide variety of colors can be found on sale.

Benefits of Protein Fiber

Protein fibers are obtained through the polymerization of casein proteins found in milk and zein found in corn kernels. The following advantages of fibers are highlighted:

- softness;

- bactericidal and antifungal properties;

- environmental friendliness and beneficial effects on health;

- good thermal insulation qualities;

- hygroscopicity and stretchability are close to natural material;

- the scale of production is limited by the availability of raw materials, since the product is also a valuable food.

Protein fiber from milk.

Attention! Among the disadvantages of protein fibers are low strength indicators, especially when wet.

Production technology

The wool production process begins with the separation of cream from milk. The result is skim milk containing 3-3.5% casein. Next, the water is separated and dried and crushed cottage cheese is obtained. It is mixed with a solution of caustic soda, achieving a thick, pasty mass. The liquid casein is then fed into spinning machines, where it hardens into thread under the influence of special reagents. All the resulting threads are tied together into a bundle, washed from chemicals and sent for tanning.

Yarn made from milk.

A method for increasing strength was first proposed by Soviet technologists. During the finishing process, the thread must be treated with formaldehyde. The solution, penetrating into the structure, combines protein molecules into a single “large molecule.” After this procedure, the surface of the fibers is smooth, while natural wool is covered with tiny scales. Therefore, the fibers are given the proper appearance before being sent to the spinning mill.

Important! When casein fibers are ignited, charred ends remain in the form of balls, and the smell when burning is exactly the same as that of natural wool.

"Healthy" supplements

Casein wool is not used in its pure form. It is usually mixed with sheep, goat or other natural wool. Depending on the additive, the material changes its properties. Smooth and shiny threads are obtained by combining with cotton and silk. Such products give a feeling of coolness even in hot weather.A mixture with cashmere gives volume and good thermal insulation properties.

Casein wool is not used in its pure form. It is usually mixed with sheep, goat or other natural wool. Depending on the additive, the material changes its properties. Smooth and shiny threads are obtained by combining with cotton and silk. Such products give a feeling of coolness even in hot weather.A mixture with cashmere gives volume and good thermal insulation properties.

In appearance, milk wool is very similar to regular wool. It also warms well and is pleasant to the body. In addition, such wool is much cheaper. After all, a thousand liters of milk provides the same amount of material as ten sheep in a year.

0

0